|

On

January 2, 2011 I started to make my “permanent” layout in my basement.

Trains were running 10 months later after some extensive work. My

layout is S Scale standard gauge. I had some thoughts about trying to have

some East Broad Top in the 20+ years I was somewhat randomly buying and

building trains leading up to actually having a home layout but then reality

sets in. There was not enough room for any narrow gauge. The

layout footprint is 12'-6" x 35'-4". The layout is 30” wide

throughout. Easily accessing trains on the layout was very important to me so

I operate from the outside looking in at the layout. I

spent a significant amount of time thinking about and testing for layout

height. I wanted to make it as high as practically possible. That makes for

more storage space under the layout and easier access for wiring and repairs.

There

are no “kids” coming here to see trains. I do not have any kids

just dachshunds. My nieces and nephews are 30 to 50+ years old. That can be a huge mistake when building a layout that is too low for “kids” to

“see the trains” that never actually come to visit or the owner’s kids likely

with minimal interest in trains anyway grow up leaving the layout permanently

lower than it ever should have been built. That can lead to a tear down and

rebuild of a new layout that is higher. I

measured my eye level while sitting in a wheeled drafting high chair I have.

I made a layout test section that was 3” higher at first then I cut it down

when I measured train clearance at my armpit while reaching to the back of

the layout. The trains just cleared my armpit. It was all DEEP thinking I

tell you! |

|

I

am 6’-2” tall. The layout is now 54” + - to the top of rail on the mainlines which I consider to be the perfect height for

me. About 4 years after the layout was built I was told about measuring “nipple

height” on the builder is perfect – sort of like everyone is supposed to know

that “rule”. I checked and that is completely true for my decided layout

height. How coincidental was that?

Added 5-17-20

I

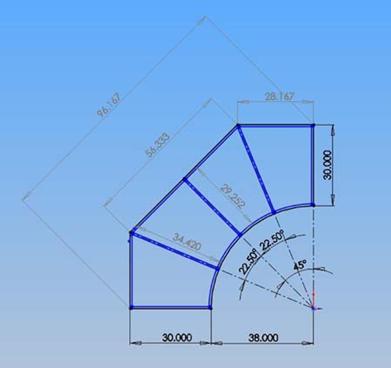

was nudged to make a track plan of my layout. The radius are

nominally 63”, 60” and 57”. Doing the plan was fun but took about 6 hours.

Luckily 1 of my Solidworks computers is right next to the layout. Trying to get

the plan right was a challenge.

I

don't claim my layout has any real railroad track design practices. I started

with 16 feet built by someone else and made the rest. It does run reasonably

well. I regularly run 40+ car trains. This is likely all of

the track I am going to have. Any more track

then this would get too congested. There is a large addition I have had in my

head for many years but that is probably not going to happen.

Unfortunately

the screen shots in Solidworks are not the best resolution but I got it done.

It is rather accurate in scale. I did some extensive measuring of the placement

of the track.

Click on photo for larger view.

Revised 11-4-20

In

November 2020 I added another mainline crossover making this the final track plan

extremely likely. Too much track is not good. I have to have some room for

scenery!

The

following pages are the history, designing and building of my layout from day

1. Maybe there are some design ideas you might like for your layout. The text

that was written at that time is shown on the pages remains mostly unchanged

even though some of it is wrong now because the plans and layout design have

changed. A lot of the designing was “make it up as I went along”. There was not

a master plan from the beginning followed.

Getting

a house with a basement also came with a major dose of reality. The plans for my 20 + year long dreamed about

but very unrealistic plan of modeling “Wildwood to Pittsburgh” layout died the

very second I walked down my basement steps for the first time while first

looking at my house in June 2009. The basement was much smaller than “the

dream” but I was somehow completely OK with that. It was truly a life changing moment at that exact second I realized this could be MY basement and this is what I was going to be

working with. In 30 actual seconds I was satisfied and said I wanted to get the

house. Reality and in some sense maturity had finally arrived at 40 years old.

I

quickly settled in on the idea of building something generic, manageable and

moveable (sectional) but not built to S-Mod Standards. It will be higher and

have sections that are larger than I could easily move for a weekend train show

set up. I had to get trains running in a reasonable time frame to keep my

interest and progress going.

My Layout

Getting started

February 2011

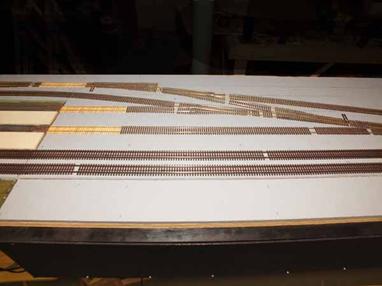

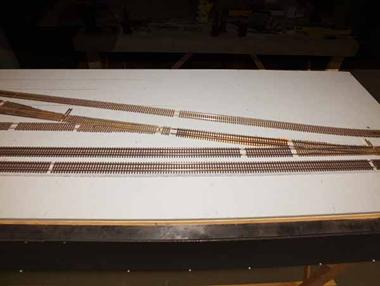

This

large S –Mod module was purchased on eBay on 10-7-06. It was Don DeWitt’s

former Grand Arbor yard module. In January 2011 I flopped

the modules down on my basement floor to see where I should start. All sections

are 30” x 4 feet. The track plan was modified a bit from Don’s original design

by Jack Bartman the 2nd owner. I am now the 3rd owner.

These are the sections shown left to right. All tracks were code 100. Even for the last 2 sections at right of

Don’s design that remained intact I did not understand the use of #4 turnouts

to enter or exit a passenger terminal. A

double slip switch just seemed like it could be a place for constant

derailments as well. Rule #1 for my layout design is all my locos I own can run

on any track without derailing. The #4 turnouts had to go. Since I was powering

my turnouts having a crossover on a bridge would be a problem to make powered.

So the decision was made to not use 8 feet of the original Grand Arbor and make

all new. Those 2 sections were eventually sold. How I modified the sections are

shown below with photos added 7-17-11

I am using 16 of the original 24 feet for my layout. It will

basically be a large loop for now with a footprint of about 12 feet by 35 feet.

That will take up MOST of my basement. My straights will be 24 feet long. A

freight yard will be the basic theme of one side. A passenger station will be

the theme of the other side. The mid 50”+ radius turns will accommodate every

locomotive I own. The track height will be about 52” from the floor. Besides

the 16 feet being refurbished everything

else will be made brand new. With the work

done so far I have wondered if I just should have just started out completely

new but I am beyond that now. It is a rolling work and idea in progress – get

trains running in my house! I am using S Helper Service flex track (Code 139)

elevated on ¼ ” thick Homabed for the mainlines. Everything

else is code 100 flat on the deck. “Down ramps” have been made to transition

between the elevated mainline roadbed and change of rail sizes.

Both ends will have 2) code 139 mainlines and a code 100

runaround/yard lead. This will be so the mainline trains can run unimpeded

while keeping switching busy. There is a “freight bypass” route on the

passenger side. Of course I will be using NCE DCC with wireless handles. There

will be 3 power regions with many sub-regions protected by circuit breakers.

All turnouts are going to be powered with the Switchmaster/Hankscraft stall

motors. They will be controlled with DPDT toggles on the running fascia track

diagram/control panel with bi-color LEDs to show route direction. I believe in keeping things simple especially if visitors come over and

want to run.

Here

are the control panel frames being constructed.

Some

people have asked me about the engine house. It is a plastic O Scale trolley

barn kit made by Korber. I bought it from Don DeWitt after buying the yard

modules. I HAD to change the sign to something PRSL.

Photos added 7-17-11

They show the sections in order left to right.

The

white panels are sidewalks for where the passenger station to going to be. I am

adding about 4 feet to them on the new section to the right.

The Corner Frames

Added 7-21-11

There are a few possible

pinch points in my basement. No matter how well I try to plan everything I just

don’t know for sure until I “see it

live” full size on my floor. Before diving head first into making the rather

elaborate frames I wanted to cut some “flop down” sheets in the footprint of

the corners to put on the floor and see how and where everything will go and

fit. I have heard of people using large sheets of cardboard for this purpose.

Luan worked just as well which is what I used.

Since the inside frame

rail is going to be curved, I could not figure how to hold everything in place

with the pressure of something curved. I decided to make a frame fixture that

will hold the pieces in place while the glue dries. I made a temporary 70” x

70” work table that will be an assembly fixture.

I designed the frame in

Solidworks but only used 2D. Everything can be measured to 3 decimals places if

I wanted. I would have NEVER been able to figure this out without Solidworks or

a computer design program. I was going to try and bend plywood as the curved

back rail, but decided to use 1/8” x 3” aluminum flat bar.

Below is my work table.

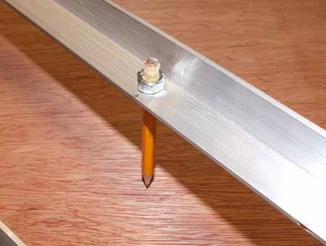

With the exception of the above frame plan I almost never fully

plan or draw anything I make. It is usually figured out on the fly. I like to

do it that way because it keeps me thinking. The pivot is a 1/2” pipe floor

flange that is reduced down to 1/4” pipe. It will eventually have many braces

to make it into a full holding fixture.

The below photo at right

is the first sheet of luan I cut out in the footprint of the frames. I think it

kind of looks like a baseball field! With the exception of the curved side

edge, I cut everything with a utility knife and long steel and aluminum

straight edges because I wanted all of the cuts to be crisp and straight. There

was also no sawdust generated in the basement.

The first sheet turned out

to be well within

1/8” of all needed

dimensions and angles. I dare say they

are within 1/16” or LESS!

The “compass” is a piece

of 1” aluminum angle. I was rather proud of myself when I thought of the

“pencil bolt” idea to secure the pencil for its simplicity. I just ran a 5/16”

nut down the pencil. Problem solved!

7-26-11

I am starting to lay out the first corner frame. I am very happy

with how it is turning out. The measurements are really close to the plan. I

have to tweak some of the lengths of the frame pieces but not more than 1/8”.

Added

8-11-11

This is the first corner frame I completed on 7-29-11. I

photographed it in my driveway

Added

8-13-11

Here are the basic frames completed with the ¾” deck installed.

I have all 4 of them built to this point now. I rough cut the curve with a

saber saw and trimmed the deck with my router and a flush cut bit. The corner frame fixture has since been

dismantled as soon as they were completed and returned to the wood pile for

recycling into future projects.

Added

10-16-11

In the 2 months since my last update I worked on the layout extensively without

much documentation of the progress.

I just figured I would the spend time working on the layout

instead of photographing and updating this page.

As of 10-16-11 all sections are up on their real legs making a

deck height of 53”. All of the above frame construction photos were on a work

table with the legs not actually attached to the frames at 48” high. We flipped

the sections vertically and back to horizontally MANY times during the wiring

process. This would have been very difficult with legs attached.

The mainline track centers are approximately 3” throughout the

entire layout. While 3” was a little wider than I would have liked the main

purpose for building the layout was to be able to run anything I

owned on any piece of track without concern of derailing or sideswiping

another train. The track centers had to be wide because of the EM-1 boiler

overhang running on the inside main possibly hitting passenger cars on the

outside main.

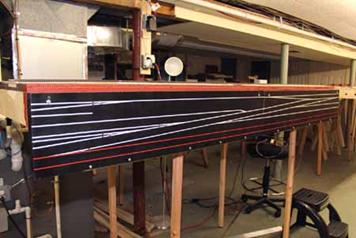

These photos are showing the laying out of the curve center

lines. I did not use the compass to draw fixed radius. I used the compass to

just lay out starting reference points. In the middle photo below you can see

where I used long wood splines (pine cut to ¾” x ¾”) that created a flowing

constantly changing radius with easements etc. I tacked in a few needed points.

The natural curvature of the wood did the rest making the laying out of the

center lines very easy as long as you don’t force anything. Making the 18’ long

splines was annoying. They broke a few times during the layout of the lines but

the results are well worth the effort.

The radius is nominally 62”, 59” and 57” for the 3 curved

tracks.

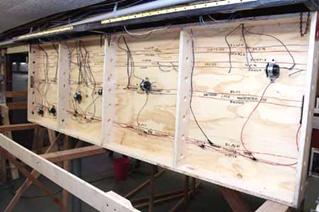

Wiring

I should have taken photos of the underside when I got the

modules. Everything was done by the previous owner in white

wire. Tracing a wire was impossible. As with any project like this, especially

wiring things are expected to go wrong. My friend Charlie Leonard is helping me

greatly especially with the wiring and finding shorts. After truly months of

trying to figure it all out I got frustrated and just cut everything off.

Finding one of the shorts on one of the old sections I refurbished was

particularly frustrating. We still don’t know how or why there was a wire UNDER

the boards of a grade crossing. That is where the short was! Unbelievable!

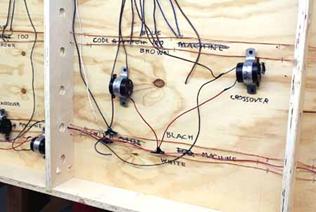

These photos show the wiring the new 8’ long section showing the

bare 14 gauge copper wire buss lines, turnout motor power buss, and Hankscraft 3

volt 1 RPM stall switch motors running at about 2 volts. With that gear

reduction they are unstoppable at full voltage. It is rather typical of what

the rest looks like. ALL turnouts are powered except 1 that is getting

spiked shut. There is no need for anyone to reach into the layout for ground

throws. There are now 9 wires running the entire length of the underside of the

layout. 6 wires are for the DCC power buss for the 3 power regions. Three wires

are for powering the Hankscraft motors as plus, minus and center tap. We have

completely isolated the frogs but they are powered. The control of the motors

and flipping the polarity of the frog is all done at the panel with a single

DPDT toggle switch on the panel. Crossovers require a triple pole double throw

toggle switch.

Bare

Wire Buss

I am likely the only person that opted for using a bare wire

buss. Lots of people said not to do it they have to be twisted pairs. Since I

was going to solder everything and not use the suitcase connectors that I heard

fail having insulation on the wires was a problem. Finding a roll of 14 gauge

bare wire was a challenge at the time. NCE recommends 14 gauge

is good for up to 50 running feet which I believe I have. The DCC components

sit right in the middle of 50 running feet going out in both directions. The

track and buss are totally gapped or insulated at the end of the 50 running

feet. NCE recommends to NOT have a connected loop of DCC it could negatively

affect the digital signal.

Everything that is needed to power track or turnout motors is

available locally on every layout section with this buss. Track feeders are

typically 6” long at the most. The buss runs right under the

mainlines that they feed.

Control

Panels

I was asked why I was making “control panels” if I was using DCC. Simplicity! I

want the learning curve to run my layout to be about 3 seconds long. Once you

master the use of the NCE handles, controlling turnouts are just flipping a

toggle switch. All turnout controls are shown in their actual place on the

linear panel fascia. The panels are Masonite that hinges downward with auto pin

striping for the track diagram. They will have bi-color LEDs to help identify

the turnout route.

The 4’ long “bridge” section only has a crossover on it so it

has a smaller control panel. All DCC equipment is being mounted on a shelf on

this section. It is the perfect ½ way point for the power buss to go left and

right. The buss will terminate at the ½ way point on the other side. I am

installing snubbers to filter and correct the DCC signal in the buss at that

point.

With

any luck I will be running some trains on my layout by 10-17-11

Updated 11-4-20

All photos and content © Lanes Trains 2005-2023