|

I

am not doing Solidworks designing for others anymore. I may be able to give

you some tips on how to do it, but by far the best thing to do is learn it

yourself and make your own parts and designs. No one knows what you want more

than you do. The learning curve for Solidworks and designing for producing 3D

master patterns is absolutely massive though.

|

|

The

following is the page archive of when I was actively doing designing, and a lot

of the items I made for me. It is extremely outdated at this point. In August

2024 I got back into doing my own 3D printing so even the text on 3d printing is

very outdated as well. I have made truly 100s of parts not shown here.

When I first heard about Solidworks I knew there had to be some

model railroading applications. I have previously made brass masters the old

fashioned way by machining a brass pattern 4% oversized. It is a VERY time

consuming process. The worst thing about it is, many times during the making of

the mold; the master pattern can be damaged or totally destroyed. So when the

mold expires, the part cannot be reproduced again without a new master. I have

had that happen to me. This process has been replaced with Solidworks and a

Rapid Prototype printer for producing master patterns.

The simplified key difference between AutoCAD and Solidworks is

AutoCAD is just a 2D drawing. With Solidworks, you can send the file to a

number of different end processes that will manufacture the part. It is a 3D

MODELING program. Solidworks is also very flexible, in that an item can be

easily modified and revised after the initial creation of the item.

See below for the master patterns I had made from my drawings. It

is really a truly amazing process. The quality was outstanding.

Prototherm and VisiJet are 3D printing materials I have used.

Prototherm becomes the master pattern for a lost wax brass

casting mold where you have a mold made for traditional lost wax brass casting.

This has a glassy smooth top surface for great finish and resolution – on ONE

surface.

VisiJet is a burnout material. It is for very low production

items. No mold is needed. You get a 1 cast part per SLA printing because it is

burned out in the curing of the investment plaster. My venture into using

VisiJet was not as successful as I had hoped. What is considered an acceptable

VisiJet parts surface by industry standards once it is burned out and cast was

by far not acceptable to me. It is good for utility

parts like motor mounts that are not seen or for difficult to cast parts, but

you will spend extensive time sanding and smoothing the brass part surfaces.

I model almost exclusively in brass, so

brass casting is the most likely way to go here. If you are modeling in

plastic, then of course you just use the rapid prototype produced plastic part

as is, but that would be very expensive!

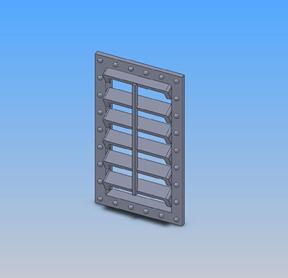

In November 2013 I made a Seaboard

express boxcar that had a

large vent in the side of the car. I had some vents made in Prototherm and used

them as the final use parts. It is the first time I have used a 3D printed item

like this and it worked out very well. Still I would NOT do this on a wear part

of something that is highly susceptible it handling. I do not know if the parts

can become brittle with age. Since the vent was completely painted I am not

very concerned with any issues happening later.

See the end details of my Solidworks

2 Page for

more details on getting urethane items made.

See videos of the 3D printing SLA

process on YouTube here (about 2 minutes) and a longer video here.

I HAVE 10

years of “dream parts”, the parts I never thought I would ever get - in my hands

now. I am making new parts all the time.

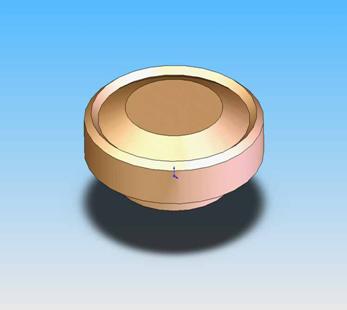

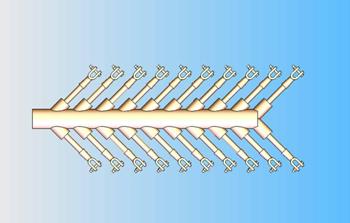

P70r

Roof Vents

The

Penn Ventilator

Capped

Vents

(I

call them stumps!)

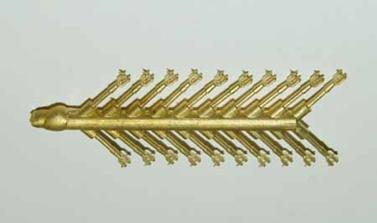

Penn

Ventilator and Capped Vents Master Pattern

This

material is called Prototherm

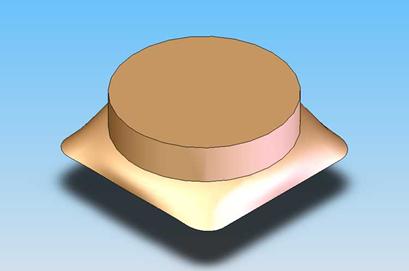

Motor

Mounts

(Made

from VisiJet)

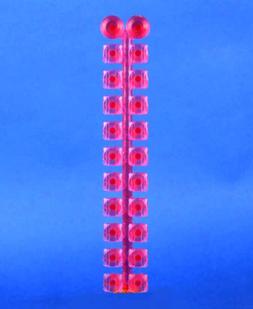

Steam

Engine Handrail Stanchions

(From

the I1)

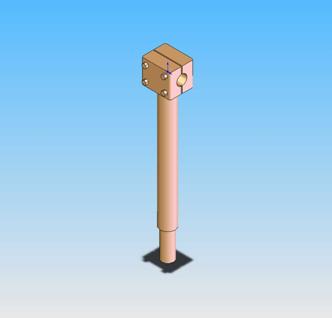

RS11

Antenna Stanchion

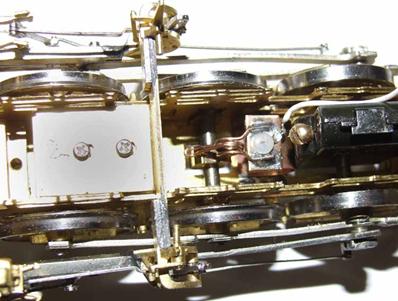

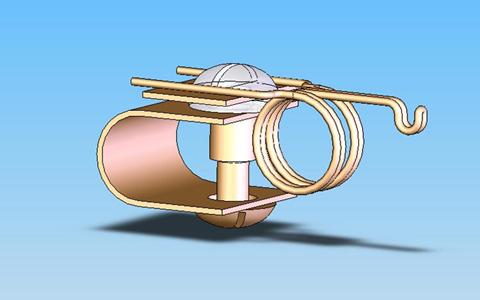

Sound

Cam Wiper Assembly

While

none of this was made using Solidworks, it looks SO nice

when drawn in 3D!

This is mounted down in the

frame right behind the sound cam on a new cross member soldered to the frame.

The approximate dimensions are 3/8’ wide x ¼” high x ¾” long. The bottom wheel

plate is between the brass screw and the C bracket. You can adjust the pressure

of the wiper finger on the sound cam from the bottom

of the locomotive without ever taking it apart.

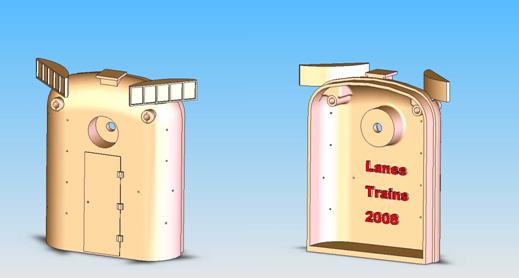

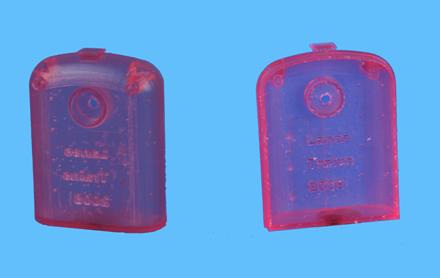

RS3

Numberboard

Actual

3D Printed Master

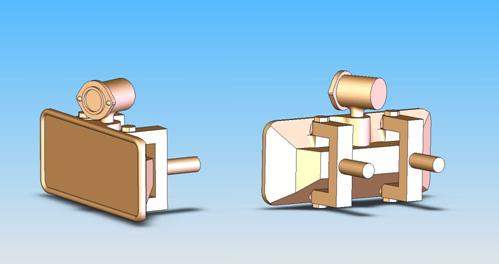

PRR

PA1 and E7 Modern Numberboard, Brackets & Marker Light

PRR

2D-F1 Archbar Truck

This

is my biggest success so far. More is to come!

This

truck is now available from Pennsy S Models

The

2D-F1 truck was used on FM GL, GLa, GLb, GLc GP, GPa, GR, GRa, GS, GSa, GSd, H22, K7, XL, X23, X24, X25, X25a and GSC. It was the predecessor to the very common

2D-F8 truck.

These

trucks have never been offered previously in S Scale in any form. It was done

as a design challenge when I was going to school for Solidworks. I measured a

real 2D-F1 truck on the GLa hopper at the RRMPA in

Strasburg PA, and then compared my sketches to real PRR drawings I have. I

crossed the prototype details and features of S Helper Service trucks to design

this truck. So it is essentially a brass S Helper Service truck that uses their

Delrin axle bushings and wheels. NWSL premium code 110 Nickel Silver wheels fit

in perfectly as well. I am not sure if P64 wheels fit. They roll and equalize

VERY well. The bolsters have the same ride height as the SHS trucks when using

33” wheels. The castings include 4 side frames and 9 journal box covers (1

extra) on the first tree. The second tree includes 4 bolsters. 1 bolster pair

is for generic installations like brass cars. The second bolster set is

designed to fit S Helper Service cars. Assembly and some drilling out of holes is required.

E7

Vent Door

Vent

for Seaboard Express Boxcar

Updated 11-29-25

All

photos and content © Lanes Trains 2005-2026