|

Because of the ending of the Central Jersey S Scalers Get

Togethers and I have my home layout running now, in February 2013 I decided to

sell my beloved 8 track wide S-Mod yard I started building in 1989 as

described below. It was a tough decision but it had not been used in 4

years. It was too much rework to somehow use it with my new home layout I was

building. For the first time since 1989 I have NO S-Mod modules. I still like and believe in S-Mod. With the ending of the CJSS Get

Togethers I will not be building more though.

The hosting clubs for the NASG Conventions get layouts set up from

regional members. I am sure I would not be driving 1000+ miles with S-Mod

sections to set up a layout at a convention. The History Of S Scale Modules S Scale to go! Don DeWitt was very active as the NASG S-Mod module coordinator

in the late 1980s to the early 1990s. He was instrumental in forming

the S-Mod Standards. The current NASG S-Mod page here. When I first got into S Scale most of the running I did was on

S Scale Modules because there were no permanent S layouts in my area. I

initially went to the Central Jersey S Scalers meetings – now inactive. Their

annual Fall Get Together is where I discovered S Scale in the first place in

1987. I really looked forward to those early meets because it was the only place for a whole year I could

run my then new to me S Scale trains. |

|

In the late 1980s I co-founded the South Jersey S Scalers with

the intention of stirring interest in S Scale in the South Jersey area and

making our own S Scale modular layout. I started my own 2’ x 20’ long double

ended yard module with the idea that you could be at a public show and bring

one train in for a rest while sending another one out without a break in the

action. The module interest never blossomed. The South Jersey S Scalers became

the South Jersey S Gaugers. They built their own Sectional Hi Rail

portable layout, and are in the process of building another much larger Hi Rail

portable layout.

Much of the below information is a

little outdated. The S-Mod electrical standards are in a slow process of being updated for DCC.

These modules were built well before DCC and were designed for Cab Control. But

the construction ideas are the same for the modules and legs etc.

Design Considerations

Setting up a layout was a careful time consuming process that

included the loadout, the bolting on of many loose legs and the hours of

fitting many loose bridge rails that were supposed to all be exactly 4” long

but never were. The module tear down on a cold drizzly October Sunday at 4:00

at the Jersey City NJ Communipaw Train Show got downright ugly. Everyone wanted to get home.

Luckily no major damage happened but there were some accidents and

bruised modules. After spending a few years helping CJSS set up and tear down

their modules, I knew that my own modules would have to be designed better.

Bill’s rules for designing better S Scale modules

Rule 1. Life is too short to put on and take legs off of modules.

Rule 2. It MUST be easy to

transport, set up and break down.

Rule 3. Avoid using the 4” loose bridge rails wherever possible. Other

scales sectional track like Atlas Snap Track and use a straight section for

this instead of loose 4“ rails. S still does not have a straight section

comparable to Snap Track. Only use the bridge rails

where the modules interface with another “unknown” module. Captive module

sections should use bridge rail sections as you will see below in Design

Features item 2 and on S Scale Modules page 2.

Rule 4. All equipment must be able to run on it. All turnouts are on my

yard module are #6 except the crossovers which are #8.

Pine = BAD Cabinet Grade Birch

Plywood = GOOD

I cannot say enough about using cabinet grade plywood. I have

been around wood all my life. My father took his apprenticeship and was

essentially a professional woodworker (Industrial Patternmaker) for much of his

life. He has woodworking tools that most would not know how to use. I simply

will NOT make a module frame or benchwork from pine or similar. I have seen it

do too many bad things over time. My frames for my original yard are getting on

20 years old now. They have not moved at all.

Back when the South Jersey S Gaugers started their first layout

they bought pine frames from a club member that was a wood shop teacher. They

were about 3/4 x 2 1/2, had dovetail joints, were screwed glued and tattooed

made from the clearest pine you would find. The frames were extremely light. I

was the only one with ANY module experience. I was the only one that said don’t

buy them. Of course they did not listen - why should they, I don’t know what I

am talking about. I washed my hands of the whole thing. About a year later I

was invited to see their progress which was extensive. There was track down

with some scenery started. The first thing I noticed was the custom bent STEEL

angles that were heavily bolted to all the sides of the "lightweight"

frames. No one even acknowledged that I "might" have been right.

By the time you cut a sheet of plywood into 3” wide strips, the

yield is great. If you contract with a

cabinet making shop that has a panel saw, chances are you can buy the wood

perfectly cut right from them in ready to use strips. There is no sawdust (from

that) to contend with.

Again, I simply will NOT use pine (or similar) for benchwork or

module frames

The NASG S-Mod standards are very flexible with track

placement in comparison to other standards such as N-Trak.

The 4 big standards are:

Rule 1. You must have 2 ¾” track centers on

double track mainlines.

Rule 2.

You must have 42” from the floor to the top of the railhead with ½” + -

adjustment bolts on the bottom of your legs.

Rule 3. You must have a 2” section of roadbed

without rails at the ends where your modules connect to other’s modules. You

can do whatever you want if your module will always connect to another one of

your modules.

Rule 4. You must have modules that are

multiples of 4’ long total.

(Ex. You cannot come to a meet with 18’ of

modules, but 16’ or 20’ is good)

Note – S Free Mo does not subscribe to the making of modules in

increments of 4’ in length rule. I do not practice the S Free Mo philosophy.

Note 2

The S-Mod Gurus have strongly suggested that I add this disclaimer….

"If you are going to want your module to be used in a loop

layout, then you probably need to make your module a multiple of 4 ft in

length. Anything other than a multiple

of 4 ft, may need a spacer module which may or may not

be available. If you bring your own spacer module to place at the end of your

module, or elsewhere on the opposite side of the loop, then there should be

less of a problem.

If you do not build a module that is a multiple of 4 ft, then you

may not be allowed in a loop layout with your module. You could be added to a branchline, IF the

branchline exists in the proposed layout.

If you NEVER want to be in a loop, then the length of your module

does not matter, except in the case where space is limited for the

layout."

That is it! It is very

flexible it you asked me.

Recent on line conversations promoting S “Free

Mo” modules get completely lost on me as we

already have a flexible established module standard. What more could you

possibly want or what part of S-Mod is too restricting? Most of the other S-Mod

standards have to do with the wiring for multiple cabs that are really not

necessary now since we are now mostly using DCC. If I were to make a new module

today I would wire it for DCC only.

I thought that I would hand lay all the track because at that

time the flex track available was on the delicate side. If you snagged a rail

in transit, it could be ripped off without a chance of it ever being repaired.

I had a Kadee Spiker at the time. I will never hand lay track again! I estimate that

I glued 5000+ ties down by hand one at a time.

Here is the track plan for my yard.

Public viewing area

6’ section 4’

section 4’ section 6’ section

Control Panel

If I could do it again, I would only make it 6 tracks wide. 8 tracks

are too much in 2’ wide. The outside tracks are very close to the edge. Luckily

no accidents have happened because of this.

Design Features

1. I went to great to great lengths to design legs that not

removable and fold up under the modules. I custom made bolts with wing nuts

welded on the heads so a wrench is not needed to put the bolts in. The bolts

run through custom made ¼” pipe bushings so the bolts never wear the wood. One

bolt is set permanently in place with a stop nut as the pivot. The other bolt

has the wing nut on it for a head. These bolts are then inserted through the

legs to lock them in place for storage. 3 of the 4 sections have 4 legs. The

one 4’ section only has 2 legs.

2. Somewhat as an afterthought, I thought of how to connect the

tracks without using 24) 4” long bridge rails. I routed the plywood deck down

about 1/32” x 1 1/2” wide. I then cut 3 aluminum strips 3” x 24” that I mounted

3” long custom made wood roadbed sections that matched the Homabed profile.

Next I mounted rails that are 4” long so they stick out ½” on each side to join

the modules roadbed. All you need is a small straight blade screwdriver and

sometimes needle nose pliers to slide the rail joiners out. When setting the

modules up all I do is set the bridge rail section in place, slide the rail

joiners out and I am done. There are NO loose 4” bridge rails!

3. The control panel folds up into a suitcase. I wanted it to be

self sustaining because there was always the fear that someone would forget to

bring a transformer to power the layout for a show. Even from the beginning the

control panel housed a powerful transformer. It has 12 “break before make” 4

button push button cab block switches. As you push a button to change from one

cab to another it disengages the current block before engaging the new black

stopping any shorts of cross cab interference. They also fit the S-Mod standard

of having 2 main and 2 local cabs. They

are kind of like the push buttons on the radios in 1960s cars. I don’t remember

who made them or where I got them now. I may have bought them here http://www.allelectronics.com as I found an old credit card bill from when I was buying electrical

supplies for it. They were a bit pricey at about $25.00 each. Now that we are

running DCC, we just put all the cabs to red. I also put my NCE

DCC Power Booster in there

as well. The control panel bolts onto the main 4’ control section. There is a

diagonal brace that bolts on and supports that panel without needing an

additional leg.

4. I thought that I could make the module so that you could use

12 feet, or 16 feet of if you did not have room for all 20 feet. It is not

possible to run 8 tracks perfectly parallel for that distance, so I now a have

a single module that is 20’ long.

5. ALL of the turnouts are powered! This comes from the public

show concept. With the modules currently stored unused for all but 1 weekend

per year the turnout machines don’t snap like they should at times. I will use

this yard as part of my layout until I get something more permanent started.

The NJ International twin coil switch machines have to be replaced with stall

motors. They will not reliably throw in both directions, mostly because the

modules currently sit unused for all but 1 weekend a year. This means a major

revision of the wiring and control panel. Perhaps once I get the module set up

on a more permanent basis as my layout the machines will perform better, but I

really doubt it.

6. The sections are electrically connected together with 20+

conductor industrial plugs. Everything is plugged in with just 2 plugs per

module. The turnouts are powered by 2 custom made patch cords. As above, I may

have bought the connectors here http://www.allelectronics.com

7. The modules are completely constructed from shop grade birch

plywood used mostly in cabinet making. It is very stable, and have has a nice

outside finish. The sections are 15 years old now. They have spent their entire

existence being stored in a basement and show no signs of warping.

8. I laminated 1/2” blue foam board to the underside to help with

stability and sound deadening. I would not do this again as I spent more time

cutting though the foam to mount components to the plywood then I feel it was

worth.

9. I used Homabed (now closed) as the roadbed for all of the track. I completely painted the lengths before

use as recommended to me as they are very susceptible to warping. I should have

used Homasote sheets, at least on the 4’ center sections because the rail is

about all that is visible above the mud in most yard situations instead of the

individual ballasted roadbeds that I have. I will probably try to fill some of

that in with something when I do scenery.

10. I used “elevator bolts’ for leg

levelers. I

used Tee nuts where I had to thread a bolt into the wood. I sometimes drilled

the Tee nuts and added extra nails to hold them in place.

11. I built a 6 tier “bakers rack” to transport them to the meets

in my then 1988 Ford Bronco II and now my 2003 Ford Escape. Everything just fits without a passenger. You will

not have a problem if all your sections are 4’ long.

With the above design features and criteria met I can walk into a

show and with less then 5 minutes of additional assistance get trains running

in 1 hour flat! The ONLY tools needed

are the previously discussed small straight blade screwdriver and occasionally

needed needle nose pliers.

Photos

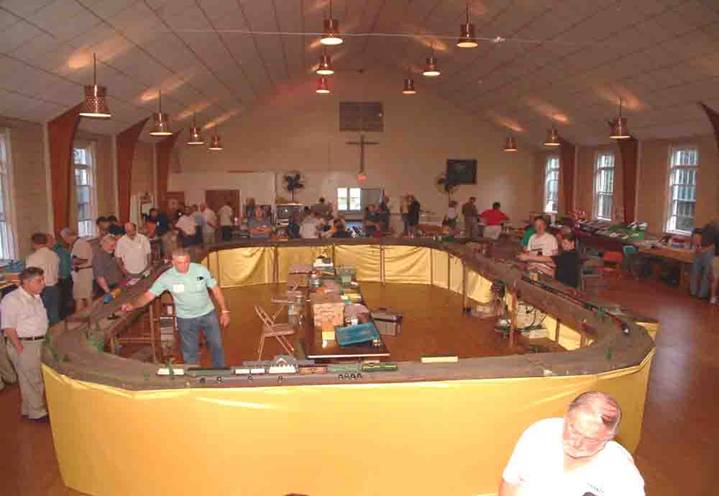

This has been the usual layout for the CJSS Get Together for the past 6 or so years. My yard is the straight

section on the left. Earlier CJSS

Get Togethers had the church hall filled with the layout including a wye

section and a branch line. The straight section on the right is thought to be

the worlds first S Scale module. They are owned by Mike Ferraro, and are about

30 years old now. It features 3 levels of switching and 3 different code rails.

Control Panel

This is the control panel before we added DCC on the left. It

view also shows the hinged lid. On the right is after DCC was added. You can

see the red panel light in the upper left that is wired hot to the track power.

If there is a short, the light goes out. You can see this from across the room.

You can see the 4 wire plugs on the front for the local cabs. We only used them

for 1 or 2 shows. I also added a nice fold down tray to hold the DCC handles

and DCC cab port in the front.

Here are 4 views of the control panel. The upper left shows the

power supply in the center. The DCC power booster gets mounted to the left of

the power supply. The upper right shows the panel back side with all the

wiring. This was the bulk of the work to make this module to the S-Mod

standards. Again, DCC makes this wiring

all but obsolete. The bottom left show what it looks like when folded up. At

the bottom right you can see the large plugs to connect the control panel to

the modules.

(See next page)

Updated 2-25-18

All

photos and content © Lanes Trains 2005-2026