|

PRSL Baldwin AS16 # 6015 A One Of A Kind S Scale Model This is the “poster child” of

my modeling procrastination habits taken to an extreme level here. As seen

below, which is a bit more blog than my usual project page, I have worked on

this model numerous times since 1993 but have never completed it. This loco

maybe be second in terms of time spent making it only to my K4 5495, which also ran on the PRSL. Starting

on 12-10-17 is the LAST time it will be worked on. It will be completed this

time. I

won about 20 PRSL Builders Photo copy negatives on eBay. Builders Photos are

my driving inspiration. It is all

there to be seen and modeled. Since I model the 1956-57 era my model would

have to be back dated and completed as shown in the Builders Photos. Still

here are great variances in details especially at the loco got older and was

shopped. |

|

I have kept much of my old text in place even though it is

obviously very wrong as seen by the 10+ year old dates.

The surviving old text is in black.

But I have inserted more and newer photos, making the timeline

slightly off in places. Some older photos are not the best, working with my

first or second digital camera in 2007. Note the evolution of electronics.

There have been 4 decoders used over the years.

How I Got The

AS16 Shell

I got

this locomotive as a shell only. I

acquired it in a “no holds barred” buy and trade deal about in about 1993. It

was scratchbuilt by a contract builder whose name escapes me at this point. It

took him 5 years to finish it and the intended customer

died waiting

for it! The builder was a HO modeler so

the S Scale shell was of no use to him. It wound up in the hands of a friend

who completely and totally taunted me by literally waving it in front of

my face and said I would NEVER own it. Even though this was well before

my PRSL interest really happened, I knew it was 1 of a kind and I wanted it. I

offered to buy the shell only on the spot for $500.00. No,

it was not for sale, not ever, and especially

not to me. It drove me absolutely

NUTS which was the intention. Well, never actually did come one day about 2

years later when I found something for sale that HE really wanted, an Overland

SD40-2 with Anti-Climbers (Production was about 20 models). I fully returned

the abuse in spades and was so ruthless that I actually got the shell

for free by the

time the trading and buying was done! I am not overly proud of it, but I got

the shell and this story is one of my all time favorites.

The Drive

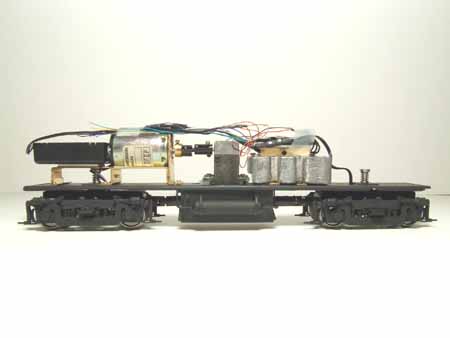

The drive

is from a run of brass GP30 produced in 1997 from Greenbrier Models. In about

2000 large components of the GP30 run started to appear on eBay. I bought a

drive, moved the truck centers out a bit, and installed Southwind Models (now

BTS) Alco sideframes. It runs REALLY well.

This is the

AS16 shell about as I bought it. Shown here on 12-15-05 it has had some work

done because a drive exists.

I knew the completion time would be extensive but so worth it. It had been about 8 years

since I last worked on it. I started making items then like the air tanks and

the long sign boards. I installed all wheel electric pickup when I discovered

phosphor bronze wire. That is very time consuming but necessary especially now

with DCC. It was probably the intimidation of how to get the sign boards around

the carbody hump on the fireman’s side that sent it back to the box for an 8

year nap. Decisions like that have proven to be good for me. When I get the

itch to work on it again, the results are significantly better because I have

improved as a modeler and now own tools I did not back then. The internet was

not available to me then as well. I can now blast out a question and hopefully

get an answer. That was the case here for a few details. I bought a Baldwin

PRSL Lettering drawing that was a great find. The original signboards I made

were discarded in favor of brass channel. It is not quite as correct because

the real signboard is a flat sheet that is frequently supported so it sort of

looks like a channel with lots of notches.

Scratchbuilt Parts

Revised 12-30-17

For

these parts I scratchbuilt in brass just before I learned Solidworks, I am not

sure I would do it any differently now. There is just an obscene amount of time spent in making these

parts.

My resurrection of the PRSLHS has caused me to work on my AS16

steadily for about the past month now. I just might get it done this time. I have

the fuel tank made. I mounted air tanks I made years ago from the last time I

was working on it. I now have

the long sign boards installed. I was eyeing how to make the cab interior. None

of it is dead perfect but it will due over what is in second place which is

nothing.

Fuel Tank

4-17-07 Update

Cab Interior

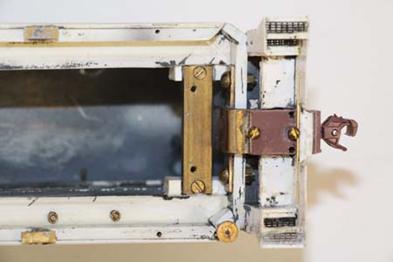

The

issue was how to make a cab floor wider than the opening in the body. I wanted

the crew to be at the windows leaning on the armrests. I threw some heavy

thinking time at it and was pretty happy with the solution. That is actually

the FUN part, figuring out how to make the part. I almost never make any

drawings. I figure it out on the fly. The cab floor is split in half. The front and back walls slide in place. A strip screws in

and clamps the 2 floor pieces in place. I originally had a cab light in place

but I am not going to do it now.

6-28-07 Update

The fuel tank is made and painted. The new MU

stands are almost done. I ran it for a night on DCC. It ran VERY well! I was

surprised in early May with the fact that LokSound makes a Baldwin sound unit.

I now have to go back and rewire everything for sound.

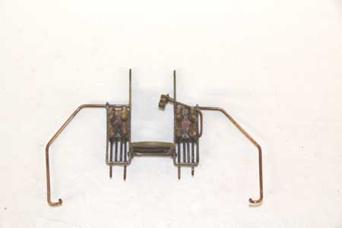

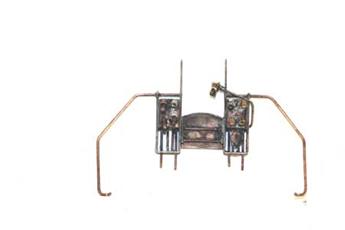

End Rails With M/U Hoses

Baldwins

were multiple unit controlled with compressed air not

electricity making them not compatible to run with other diesel loco builders.

Looking at AS16 photos there seemed to be many different configurations of M/U

valves and hoses. The first photo is how I made the end railings in 2007. I

never really liked the 8 train pipe valves per end as that was not correct. The

other photos are from 2017 when I wanted to fix them. I recycled the train pipe

valves, cutting them in half so I could attach hoses to them. They rest are

elbow castings trying to make 90 degree elbows look like 45 degree elbows. I

had great fear this whole thing would fall apart while making the changes but

it did not happen. I used clips and a wet cotton ball for heat sinks. Work like

this simply cannot be can’t done with a conventional soldering pencil. You need

a resistance soldering unit like the PBL 300 watt Hotip. It all went really

well. I still have to add some chains to both ends.

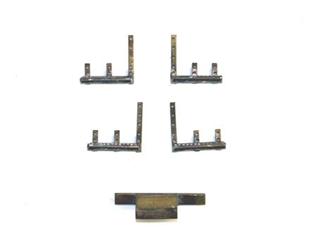

Footboards

I

wanted footboards with some form of an open grate. I am not sure if they were

round or rectangular holes but good enough. The other piece will go between the

footboards under the draft gear.

7-20-07 Update

The sound unit is in. Wiring DCC and sound

can be a challenge in the narrow hood units like the AS16 and GP9. I try to fit

in the biggest speaker possible. While the sound is not going not straight out

of the top of the shell because there are no fan openings etc. as I usually

prefer, I am taking advantage of the large screened openings on the sides.

Since I am currently using LokSound units, their 100 Ohm speakers really limit

the available speaker variety. I really wanted lit numberboards, but after a very

close call with slightly melting and almost ruining my GP9 I decided against

it. I have put a lot of

additional time in making sure the model stays together. Major brass detail

parts like the signboards are getting bolted on with 00-90 screws being used as

studs. Other parts are being pinned with wire when they are glued together.

After all of this time and effort I do not want to have to repair it and do

touch up. This is the very reason why I model almost exclusively in brass. A

good solder joint is forever.

Note the cast weight I made next to the gear

tower.

Loksound decoder And Soundtraxx Speaker

I co-opted a Train Control box from a parts K4 pilot. As

shown in the Builders Photos, there is an up and over walkway. I made the walkway part pretty easily. The

biggest anxiety attack was

when I was drilling the holes through the deck to mount the parts. I got pretty close but still had to make a

little wiggle room to get them lined up perfectly

.

On 7-24-07 I took the biggest leap of faith so far when I

stripped the paint. After working on the shell for a few months now I was

pretty sure it was made from Evergreen styrene. In spite of getting $45.00 of

Chameleon Stripper, I actually had visions (no make that nightmares) of pulling

a sagging goopy blob of plastic from the soup when I dunked it. I can now

attest that the Chameleon Stripper (no longer available – Scalecoat makes an

identical plastic stripper) was safe for at least this shell and another one I

stripped yesterday. I did a little test on the inside before going for the big

dunk. The paint did not fly off but

there were no signs of damage or crazing. 2 hours later after some pretty

steady scrubbing with a small stiff paint brush it was pretty good. A few steps

got knocked out in the fray but they will be repaired.

10-8-12

I am back on it again. Procrastination sometimes works on

my favor. There is now a Tsunami Baldwin decoder. I ripped out the LokSound

unit. I never really liked it anyway. I am getting custom decals made by Jerry

Glow. I have moved on to using RailMaster Deep Bass speakers with the Tsunami.

These are all good things.

10-12-12

The Tsunami is

installed and it is running very well. Some details are made and are not

installed yet.

A lot of details

and rework have to be done.

This is the “test

run” portrait on 10-12-12

A YouTube clip of this test run is here

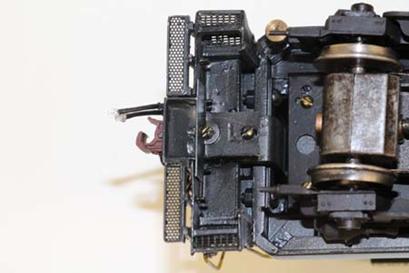

Coupler Mounting

12-10-17

This

coupler mount was likely done before I stripped the paint in 2007. I had GREAT

concern of a collision or hard coupler hit, and if the pilot would survive the

impact. The plastic has proven to be a bit brittle. I would have rather

attached the couplers to the drive but could not see how that would work while

filling in the draft gear and pilot. I went to some rather extreme building

making this elaborate coupler bracket tying it into much thinker areas of the

shell.

I

reworked the housing that goes under the draft gear. I really did not have a

plan for how to do it well in 2012. It is a bracket that screws to the bottom

of the Kadee coupler box. This makes coupler replacement possible because it is

all removable. The bracket is a bit wider than the draft gear for additional

strength and protection.

Many projects have been done since I last worked on this. In 24 years

after getting the loco shell it is time to get it done. Today I installed the

LAST of 4 decoders and speakers. This first photo is a Mini Soundtraxx Baldwin

Tsunami2, Current Keeper capacitor bank and a RailMaster DLG8 speaker. I did

not cut grooves into the backs of the wheels for this loco. I started doing

that later. With the Current Keeper that fixes many pick up issues. No lights

yet. The last time I worked on it was going to be incandescent lights. I am

using all LEDs now, and have to make a complete new light system. I also

installed much better driveshafts than the cobbled together pieces I was using.

It was great to pull a PRSL train of my “HOT” PRSL P70 that did not exist that last

time I ran it in 2012.

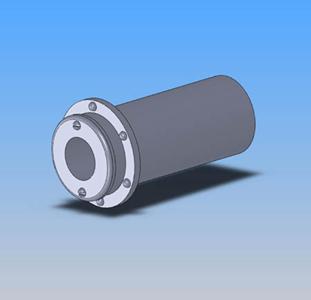

Added

12-30-17

Let

There Be Light

I consider lighting to be slightly more important than sound.

Some of my locos can have just a motor decoder only but they WILL have a nice

lighting system. The first photo is a Solidworks screen shot of the marker

lights. The next photo is the headlight bezel ring. These are the only 3D

printed parts on this loco.

This is a BTS 07079 Alco 2 bulb back up light http://www.btsrr.com/btsdet01.htm

that just happened to fit perfectly in the existing headlight holes. I soldered

it into a round brass tube that is also the led holder. I really wanted to use

3MM LEDs because I like very bright headlights, so I modified the casting

extensively. The above bezel fits around the outside of the backup light

casting. A clear lens will cover the casting.

Finally some new progress. I

wired the 3MM and Pico red LEDs for the marker lights. The marker lights are

not really as large and bright as shown in the below photos. The marker lights are

translucent red and with the red LED really GLOW. It should not be that large

once the shell is painted. This is the first time the marker lights have ever

worked. The bottom right photo is inspiring for when it is really done and

painted.

Ready

For Paint

Added

1-7-18

I looked at the model through my “current” eyes and saw some

things for the first time I needed to fix. There was no “hinges” or handles for

the doors under the cab. There was no windshield wipers.

I glued things on that have been loose and test fitted for many years. It was a

great feeling to know the build is done. Onward to painting.

Completed

1-11-18

After all the starts and stops over many years I am SO happy it

is finally done. It is a lifetime project that took on a life of its own. But

some things that are important cannot be rushed. The below is not the model I

could have made even 5 years ago. It is significantly better, and hopefully I

will not have second thoughts on what else I should have done to it in the

future.

Maximum

PRSL

I

don’t think I can possibly squeeze any more PRSL in this photo. All of the icons

are finally here, RDC M405, AS16 6015, and K4 5495. They are the stars of my

Wildwood painting completed in 2009. All I need is Wildwood Station!

Added

1-20-18

A week after completing my AS16 I rediscovered this photo of a

test run on a friend’s layout on 3-28-07. What a difference start to finish for

my completed model!

Added

4-6-25

There have not been many PRSL slides for sale on eBay for a few

years. This one appeared in March 2025. It fell into my “it’s different” category

so I bought it. 6015 has seen better days waiting in Camden to be scrapped. No

date was on the slide.

Updated

4-6-25

All photos and content © Lanes Trains 2005-2025