|

American

Models made the S12 for many years but I never got 1. They had and still have

the wrong trucks. American Models used trucks for the Alco RS3 instead of making

the correct AAR Switcher truck below. It was not an important enough detail

to make the correct trucks given most of the S market is Hi Rail. |

|

The

S12 was a significant loco for the PRR and especially the PRSL. I saw a B&O

S12 on eBay first so that got the buying started going from none to 6 in a

year!

This

is the B&O S12 I bought first. You can see the Alco RS3 trucks. They are

not bad but are not correct either.

Making 2 Locos Into One

I

had heard of how others were modifying their S12 with correct trucks. When S

Helper Service was in business you could just buy the correct AAR trucks and

cobble them to the American Models frame. Of course I never bought any loose

trucks when it was easy. Now I have to buy a perfectly good S Helper Service

switcher, gut it like a fish just for the trucks, and hopefully sell the

remaining carcass. It is still a rather expensive process bashing 2 locos into

1. Not all of my S12 will get the correct trucks. The above B&O is staying

as is. But for every S12 I correct I have correct RS3 trucks for that project –

some day.

RS3 to S12 Custom Frames

There

is a bit more of a tie from the RS3 to the S12. This project started working on

a RS3. The brass S Scale RS3 drives from 1983 died with age so I wanted to make

new RS3 drives. This RS3

came up for sale on eBay in November 2016 with an expertly machined custom

frame using American Models trucks. It was absolutely brilliant. I

measured it extensively, designed it is Solidworks and tried to get more

machined but they were too expensive. A freind suggested 3D printing of metal,

something I had never done. The first RS3 frame had shrink I did not know about

and was not usable but it was the proof of concept needed. This definitely was

the way to go, and was much cheaper.

At

the same time as the RS3 was sold, I bought a S12 with this custom frame very

likely by the same machinist. The correct AAR trucks were included. I wished I

knew who he was because he had “serious machining skills” and was a basher like

me. Based on what was sold he was a PRR modeler as well. This frame was hogged

out of brass bar stock. This was the CORRECT frame and trucks for a S12. I

measured and designed it in Solidworks as well.

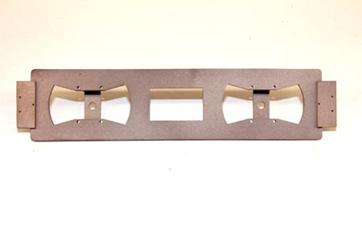

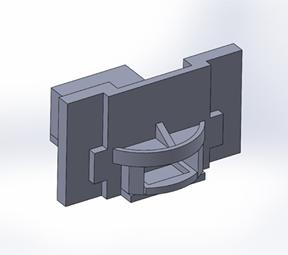

This

is the first print S12 frame. It was much closer to being usable than the RS3

frame, but needed some tweaking.

Yet

another unexpected aspect is that the stainless and bronze composite material

was amazingly hard and could not be drilled or easily machined. I decided to

get medieval with it by trying to anneal the metal. I got it dull cherry red

and wondered if it would delaminate or fracture. Not in the slightest. It is

all but a solid piece of metal just like bar regular stock. The annealing

helped a bit. I could get some milling done but my Big Green Machine was not

happy. Note the chips turning brown. Drilling small holes is still not possible

though.

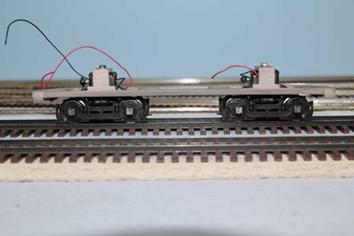

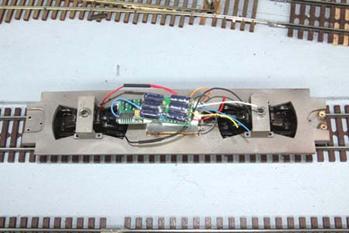

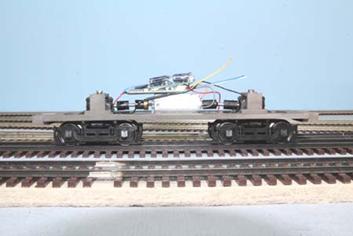

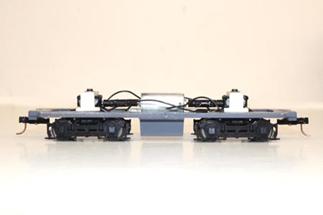

Shown with some very quick and dirty temporary decoder installations. The NWSL 2032D-9 motor runs well.

The original and my copied S12. The current plan is making 2 for PRSL, 2 for PRR and 1 for Reading as a DS-4-4-100.

Added 9-1-19

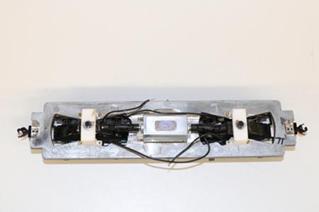

This

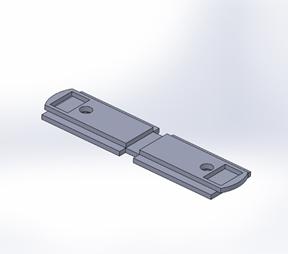

is my S12 frame V2019. I have abandoned trying to make the S12 frame with metal

3D printing. Dialing in the shrink factor got expensive. It is more “work” but

machining the original frame is free. Any time I can make chips fly is just

fun. A man has got to occasionally get in touch with his inner milling

machine. The conversion to the correct trucks is $10.00 worth of 3D printed

brackets. That is all that really needed to change anyway. When the machining

is done the original frame is all but reduced to a flat plate but it works and

fits fine. I plan on making a correct draft gear so that will move the couplers

to the shell and require more frame machining by removing the coupler pad.

The

NWSL 2032D-9 motor is VERY low profile. The cab is empty! You can put an

interior in it. I do have a WOW4 installed. The slow speed capability is just

awesome.

Added 9-28-19

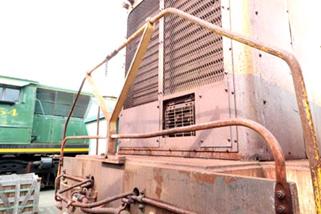

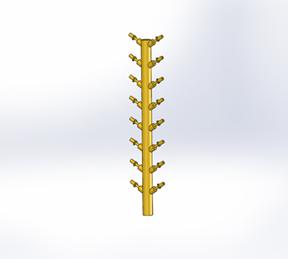

On

9-2-19 I went to SMS Railroad in Logan Township NJ that is likely the last

place in the country running Baldwins on a daily basis still making a

living. I did some measuring and had

some new parts made. Everything turned out really well. The draft gear is

perfect with correct coupler height. I also made the end handrail bracket and

handrail base for the side handrails. There are a few more things I want to

make. I have to look at air and fuel tanks, and pilot steps. The Shapeways

brass casting service is a bit expensive but just what I need here. The quality

is absolutely excellent.

These are Solidworks screenshots.

I

used holes already in the shell for mounting the original handrails. The bar across

the handrail posts was added by Shapeways so they could print it. It was easily

removed.

Added 1-12-20

Handrails

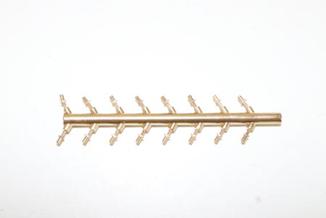

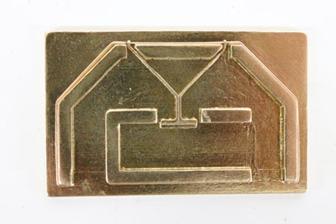

This

is my S Scale universal 1 size fits all handrail kit – some assembly (bending)

required. I have been using phosphor bronze wire for over 25 years. It is much

better than brass wire. This is a handrail bending fixture I designed. There is

no way I could have bent the end handrail uniformly for 6 locos. I start at the

lower left and bend until the posts have to be added than finish the

wraparound. The “C” in the center is for the side handrails. I had to modify it

slightly for that use.

Progress

has been a bit slow. Making handrails is very time consuming even with my

custom parts. The handrails are mostly done here. I am allegedly doing it 5

more times!

Updated

1-12-20

All photos and content © Lanes Trains 2005-2020