|

Purchased 3-28-12 Completed 1-16-14 Chad

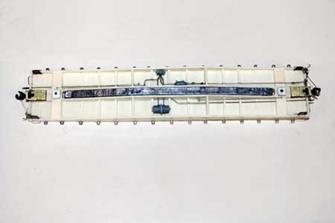

Boas made a urethane casting of the Seaboard F-6 flatcar in 2012. I bought 1

to just support the project with the wood deck and decals from Jerry Glow.

That was the total extent of the kit and purchase at that time. At the end of

2013 on a complete impulse I decided it was time to build the car. It was

just after another project of making a Seaboard

Express boxcar. The

only items I did not already have were Grandt Line stake pockets and the

eventual decision to buy Tru Color paint for the Seaboard freight car red. Bare Casting |

|

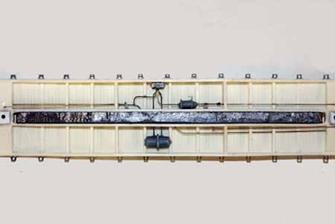

Centersill Weight

Since

it is urethane and very light I had to add weight because I wanted to be able

to run the car without a load anywhere in my trains that usually have a lot of

brass cars. I figured milling out the centersill would be easier than trying to

hide weights everywhere else. Chad did

a nice job of simulating the underside of the wood deck so I wanted to keep

that. I

also wanted something “metal” to stabilize the urethane to change any

possibilities of it warping.

I

wanted to use my milling

machine to

cut the centersill slot. But the milling machine could have chomped the car into

a mangled mess in 1 second flat if it popped out of the vise so I decided to

cut the weight slot with a Dremel and carbide cutter.

Many

years ago I made simple wood molds to cast weights. This would be easy. I laid

it out on a small piece of pine. I hoped that the weight would pop right out

but since I was only making one I would split the mold apart if I had to.

Milling the wood for the mold was fun. It is the first time I have done it with

this machine. The straight side was easy but cutting the diagonals was tricky

since it is BILL powered not CNC. I placed some 1” wire nails in case it needed

help coming out of the mold. I forgot that lead bubbles up so when I poured for

a full fill the center was thicker than would fit in the centersill. COOL! I

get to use the milling machine again. I took about .030 off to get back to the

.25 width I needed. I did NOT have to split up the mold to get the weight out

so it survived to cast for another day. When I was done machining the weight

with the exception of the length that came up a little short for some unknown

reason it fit perfectly! There was a little WHOOSH when I slid the weight right

into the centersill! According to my rickety old mail scale the weight cast out

at about 4 ounces which is just what I was hoping for.

I am not encouraging anyone to cast lead weights. Molten

metal of any kind is dangerous!

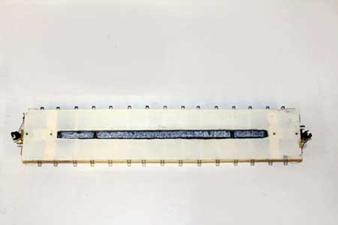

Detailing and Ready for Paint

Significant

effort went into making the underbody have a brake system. I had limited

materials to work from so I don’t claim it is perfect, but much better than the

no detail I had originally planned for this car. It was mostly a Grandt Line AB brake set with various wire sizes. Most of the

wire is phosphor bronze especially the brake wheel shaft.

Other

items needed were S Helper Service trucks, Grandt Line stake pockets, my brass

draft gear, cut lever brackets and brake wheel shaft ratchet, 4 Pacific Rail

Shops stirrup steps, brass train pipe valves, and wire grab irons, some small

pieces of chain and a brake wheel – recycled from another project. The cut

lever brackets were made off the car and glued and pinned in place. But I DID

do some very fast soldering of items while ON the car using my Hotip resistance

soldering unit! I much prefer soldering to any other form of joining 2 items.

It is tricky but no urethane was harmed.

I want to mention about “pinning” pieces together especially if

they are mixed materials. While photos

would be better, for this model I added small pieces of .025 wire

to the back of the draft gear and drilled a matching hole horizontally into the

body bolster. This made it so I only had to use one screw to attach the draft

when used with a liberal amount of ACC glue. The cut lever brackets were

soldered to a piece of brass angle. On the back of that angle I soldered a wire

that went vertically through the end sill. There is nothing that annoys me more

than when detail parts come off a finished and weathered model. This

significant extra work really helps tie the model together much better.

Completed 1-16-14

List of materials

Any Google search will find the suppliers

Updated 2-14-23

Jerry Glow decal artwork is now owned by Tichy

S Helper Service was Mikes Trains house which the SHS brand was

bought by ScaleTrains

Flat

car body & wood deck Chad Boas

Decals Jerry

Glow

Trucks

S

Helper Service

Stake

Pockets & AB Brake set Grandt

Line

Tichy

Phosphor

bronze wire

Brass

train pipe valve BTS

(Bills Train Shop)

Tru

Color paint Seaboard Freight Car Red

Kadee 808

Couplers with the pins cut off

That

is the end of current commercially available items on my model but you should

be able to complete a car with them.

Brass

cut lever bracket, brake shaft bracket, draft gear, brake shaft pawl – made by

or for me.

Brake

wheel Recycled

from another car project.

Updated

2-14-23

All

photos and content © Lanes Trains 2005-2024