|

I

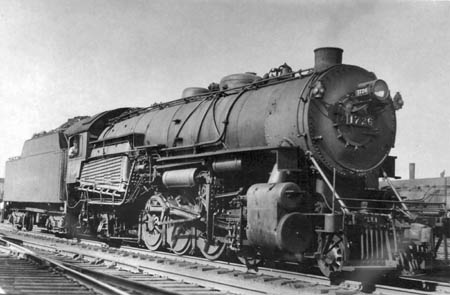

was exchanging emails during October 2017 with my friend Dick Karnes about

him making me a Reading G3 when the conversion turned to a Frank Titman built

2-8-2 #1726 he had, and I did not know existed. The G3 is not getting built

for now but he said the 2-8-2 could be for sale. Dick bought it to repurpose

it into a New York Central loco. There will never be any more Frank built

locos, so I had to SAVE it and keep it as Reading. And so I did. This

is the first photo I saw of 1726 on Dick’s layout. The deal was done. While

it might not have happened on the real Reading and definitely not on the

PRSL, I knew 1726 would run well in a doubleheader with my I10sa 2003. |

|

When

I got the loco I had to regauge all of the wheels to current NASG standards

which meant pulling each wheel out about .007. The center drivers are blind so

that was easy. Code 125 wheels can be a

problem on my turnouts so I narrowed the trailing wheel a bit. I also changed

the tender wheels to Northwest Shortline code 110 nickel silver wheels. I also

wanted to change the motor out and install DCC and a LED headlight. I wanted to

keep to as close to what Frank built as possible. For me these locomotives are

a part of S Scale history I am preserving. “10 63” was stamped in the bottom

plate so Frank may have built this in 1963 which is very cool. So I changed the motor, but I can’t just have

this sit on a shelf or in a box. It has to RUN. I am sure that is what Frank

would have wanted.

New Motor

This

is a motor that Fred Rouse was selling when he owned S Scale Loco and Supply.

It might not look like an expensive can motor, and it is not, but it runs VERY

WELL. It is the same motor that is in my I10sa.

DCC

There

turned out to be a bit more gear noise than my I10sa so I installed a WOW4

sound unit with Keep Alive. This is a quick n dirty test on 11-11-17. The Wootten firebox is big and makes decoder installations

easy.

All Wheel Pickup

Making

all wheel tender pick up is a very time consuming aspect of my DCC installation

process. It takes most of a Saturday to complete but must be done though for

excellent operation. Cutting grooves into the back of the wheels, and bending

the wires so the have just the right tension for pick up without dragging is

very tedious. This is of course the mock up. I use nylon screws for the final

installation.

Headlight Repair

This

is 1 of my more difficult “brass” repairs - ever. This locomotive is very much

“mixed materials” most of which I don’t know what and where they are. There is

a lot of brass in the construction but this is by far not a brass locomotive.

In

drilling out the headlight to fit the LED, the headlight bracket popped off the

boiler front. I wanted to SAVE the decals which were right next to where I

needed extreme heat to solder the bracket back on. Oh,

and where do you clip the GROUND to for making the joint?

I

clipped on some cotton balls soaked in water for heat sinks for the numberboard

and headlight, used the drill bit for a ground, hit my trusty HOTIIP resistance

soldering unit to 5 and created a steaming hell in the middle of my boiler

front. The excess water had to boil off before soldering could begin. It took a

few times trying. I got a significant blister on my left index finger and

scorched some cotton but it got done. You could never make this repair with a

torch or any normal soldering iron.

Completed 11-16-17

There

are still a few small things I want to do like add a headlight lens, a fireman

figure, and boiler front MV lenses but it is pretty much done. I got some new

camera lenses while this was being worked on so I had to try them as well!

Doubleheading With I10sa 2003

Updated

2-25-18

All photos and content © Lanes Trains 2005-2018