|

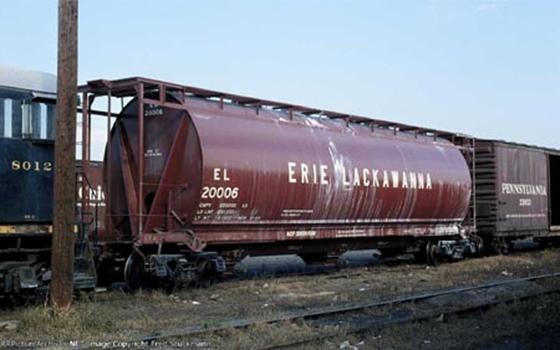

This

is a covered hopper made by Lionel as American Flyer starting in 2015. It is

an ACF hopper from 1965. My “modern” is lacking in rolling stock. Lionel made

some cars with scale wheels. The trucks have rotating bearing end caps which

were pretty interesting. But of course there are problems with Lionel making

S SCALE cars. |

|

Lionel

was trying to sell them at about $80.00. I got mine as a goof in January 2019 on

eBay new in the box for $40.00. It was car body that was new to me and a bit

more modern.

Penn Central

In

all the eras and railroads I own rolling stock for and have modeled I have

mostly skipped everything for Penn Central. It just does not appeal to me as a

“dark ages in railroading” thing. This is my 2nd only Penn Central

car. I have no Penn Central locos. I am not sure if the paint scheme on this

car is correct, and it does not matter to me. Other schemes Lionel offered were

clearly made up “foobies”. This is the car straight

from the box. I had to knock the Lionel stink off of it.

Fixing The Problems

The

car is too high because of a very weird truck bolster. It is too shiny. The

build date is wrong. Lionel uses the date they released that car for sale. And

Lionel somehow managed to get the wheel gauge wrong. Simply

amazing. Most of the work I did to fix the height problems can be

skipped by using Ace or S Helper Service (now owned by Mike’s Train House)

roller bearing trucks. You may have to fiddle a bit to get the coupler heights

right. But then it would not be a project would it? I wanted to recycle the side

frames and wheels so the bearing end caps would rotate.

Fixing

the car height was pretty simple. Enter Ben

Trousdale AKA Ben Central Shops. Ben designed and sold 3D printed truck

bolsters that fixed everything. His design was just great. The coupler height

was perfect. I actually bought the bolsters 2 years before I bought a car. It

was not that much of an accident for me that my Penn Central car was fixed with

Ben Central parts.

Another

thing I did was grind .015 off the wheel tread with a Dremel. They wheels were

code 125 which causes flash short problems on some of my turnouts. I made them

code 110. You can see that in the below photos.

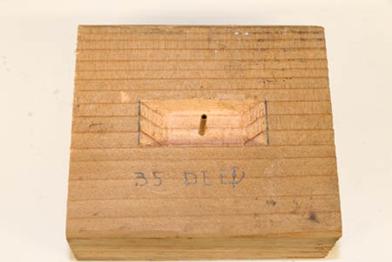

Whenever

I get to use my milling machine it just adds to the fun of the project. I like

to make my cars heavy. I used my milling machine to make wood molds and cast

custom lead weights. Most of the time it works well.

This time it was about 3 hours of work only to gain 3 ounces, not as good as I

had hoped. What I thought would fit without being seen did not so I had to keep

milling the weight smaller. The brass tube was so I did not have to drill a

mounting hole.

Completed 1-26-19

This

was just a quick little project to get a different car. I did not change the

build date. In 100+ sets of decals I did not have any that would work. Good

enough. While maybe not as obvious here I used a mix of Scalecoat flat glaze

and gloss to clear coat the car and knock the high gloss off. It is a nice

satin finish now like a 1950s rat rod!

Added 1-27-19

From Bill Volkmer – Former PRR employee

If there was a job on the railroad Bill has done it

If

I remember correctly those covered hoppers could only be described as a royal

Pain in the posterior. The NYC began getting them about 1964 and labeled

them "Flex-Flo" hoppers. Not long after they hit the road they

began derailing for no apparent reason. The prevailing theory was that

they had an unusually high center of gravity when loaded and with the

prevailing poor track maintenance, they would rock off, on even a slight curve.

PRR efforts to protest to the NYC merely drew "fix your damned track"

responses.

Then

one fateful night in winter 1967, in fact it was a bitterly cold night with 6

inches of frozen snow on the ground, we had a derailment between Newberry

and Jersey Shore with a couple of those covered hoppers. We called the

wreck train from Renovo and took cross elevation measurements using the wreck

derrick for weight which I normally insisted upon.

The

speed tape indicated the train was going something like 28 mph, the track was

pronounced "within spec." and we couldn't find any visible mechanical

defects on the covered hopper. Normally when that situation arose at a

wreck we (MM and Trainmaster) would twist the Track Supervisor guy's arm and he'd

call it in as a "broken rail" which was always considered to be an

act of God so we could all go home and back to bed.

Well

on this particular derailment nobody yielded and we seemed doomed to freeze to

death out there at the derailment scene until we mutually agreed to a cause. So

we finally got Philadelphia to buy into the theory that even though the track

was in spec and the train speed was legit, the high center of gravity of the

car caused it to derail.

Bottom

line was that from that day forward, a written 19 order was written to each

Conductor and Engineman on the Northern Region that "trains containing

loaded NYC covered hoppers in XXXXXX number series must not be operated between

15 mph and 40 mph for extended periods of time."

Those

had to be the most bizarre train orders ever written.

Updated 1-27-19

All

photos and content © Lanes Trains 2005-2019