|

|

|

Pennsylvania

Railroad K5

The Mighty PRR was heavily involved with steam loco development

with their own design, manufacturing and test plants. With the PRR K2, K3 and

K4 locos running the PRR wanted to see what would happen if essentially a M1

boiler was put on a K4 drive so the K5 was born. You can see the much larger

boiler when comparing the K5 to the K4. The larger boiler produced more power

but did not add enough weight to utilize that power so the tractive effort was

reduced from the hoped potential. That is why only 2 were made locos 5698 and

5699. Comparison data to the K4 is here on

Wikipedia.

American

Flyer K5

This A C Gilbert American Flyer PRR 312 K5 is the last piece of my original trains I have left. I sold my American Flyer collection in 2016 which were my original trains and snatched this from the boxes just as everything was leaving. This was my 12th birthday present bought from Chick Viggiano for $30.00 when he was renting space in a flea market in Pitman NJ. I had to convince my Pop to go for the extra $5.00 to get “the metal one”. It is a 312 as built but we converted it to a knuckle coupler. I ran this loco a lot. Once I knew there was a difference between the K4 and K5 I forever have wondered why Gilbert picked the K5 to make in model form that there was 2 only made by the PRR instead of the K4 made 425 as one of their most successful locos ever.

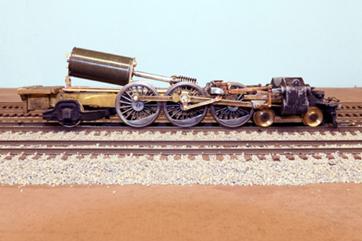

This was a surprise project posted to the S Scale I/O list. If

it was a kit I never would have bought it – too much like work to get it

assembled. This is what a new kit looks like.

But this was assembled and for sale which I bought for $75.00.

It is shown below as received no work has been started. No tender was included

so I got out a spare Omnicon K4 tender to see what that looked like. I have not

decided whether to use the brass tender or get an American Flyer tender. I

liked the historical significance of the scale conversion drive I have heard of

but never seen before. Also as a way to be able to run a K5 now as a

replacement for my original 312 just like my American Flyer 0-8-0.

This

conversion drive was a collaboration of some sort between Nimco

and Midgage

Models. I am not quite sure who supplied what and when so I will include both

descriptions from the NASG Website.

Midgage

Models

???:

started

by Bill Stewart.

1950: Gene Fletcher joined the company (he was the accountant), and Bill wanted

to sell it, so Gene bought it, renaming it "Sylvania". Gene only kept

the passenger car line. He was located in Rehobeth,

MA, and helped found the Bristol S Gauge Railroaders club in 1948 (for more

history about this club see the October 1997 NASG Dispatch issue).

2003: Gene died.

Most interestingly, the company was set up in one end of one of the two New

Haven box cars that Bill owned and placed on his property. The company produced

box car, express reefer, and smooth-side aluminum-extrusion passenger car kits,

as well as trucks kits. He also produced a kit for a scale PRR K-5 Pacific that

used American Flyer Pacific boiler and tender superstructures (the

"scale" drivers were provided by Nixon Model Co.). The company sold

cast white-metal kits for superstructures for the Alco S-4 and EMD SW-1, which

were intended to be powered by Miller power trucks.

Nixon Model Company

Often found abbreviated as "Nimco"

(Nixon Model Company), their trade name for their S-scale product line. The

company was the leading manufacturer and a dealer of "scale"

equipment from the late 1940s up to about 1960. Paul Culp and his brothers were

the ones who actually made the tooling and dies for Nixon.

Nixon produced conversion kits for American Flyer

locomotives, such as the 0-8-0, the PRR K5 (released as a complete kit by

Midgage Models), the NYC Hudson, the RDG 4-4-2, and the UP Northern.

These kits contained replacement wheels/axles for tender, pilot, and trailing

trucks as well as scale drivers and axles. The axles had "D"-shaped

ends, and the zamac driver centers had "D"-shaped openings to match.

This design assured proper quartering. The modeler had to remove the AF

drivers, axles, and worm gear, then use the reverse procedure to install the

scale versions. The modeler had to press the drivers onto the axles between

vise jaws to keep the drivers perpendicular to the axles. Rectifiers were

separately available to allow for DC reversing of these converted locomotives.

This

was from the true craftsman era of S Scale borrowing rather heavily from

American Flyer. But note the brass tender next to the American Flyer K5. They

are really close the same size. American Flyer was much closer to the correct

1:64 scale than probably all other “toy trains”. Earlier versions of the

American Flyer K5 had an O Gauge 3 rail drive possibly with the exact same

shell. To the best of my knowledge there are no modifications to this K5 shell.

This conversion drive was made and rather well to fit the K5 shell. Again - I liked the

historic aspect of what it was like and truly necessary to try and be as a

finer modeler in S Scale than the typical American Flyer layout from the 1950s

to 1970s. I call it the “mans man”era where you had

to build pretty much everything and earning S reputation as being “The

Craftsman Scale”. I get to use it in 2022. This is my oldest piece of rolling

stock for sure.

Conversion Drive

All

wheels are code 125. With other locos of this era I have replaced all wheels

with code 110 except the drivers. Somehow the drivers are in or very close to

the current NASG wheel gauge. 1 axle is a little tight. Note that the axles

cannot be easily removed to pull the wheels. With the 50 year old cast zamac

driver centers I am very hesitant to do much about correcting the tight axle

unless the loco derails all the time. I might have to risk pulling that axle

into correct wheel gauge.

The open frame motor is huge but runs really well at least when test running holding it up in the air. But I am concerned with the amp draw. In about 8 of my locos that came to me with open frame motor I changed all of them to can motors. That is likely to happen here as well. Besides the amperage draw open from motors don’t play will with DCC. As shown above the drive, shell and large boiler weight weigh over 4 pounds. This should pull the paint off the wall!

Boiler Weight

I

think the boiler weight was cast in place in the boiler shell! I thought that

was pretty cool! There are no screws holding it in place. The shape fits the

boiler interior too perfectly. It barely moves in the shell.

Budget Project

This

is by far not going to match the detail level of my 3 Omnicon K4 and other

locos I have but that is fine. I already had some parts like old school K4

tender truck castings that might be Nimco as well. I

have Omnicon pilots left over from modernizing my other locos and steam loco

handrail stanchions I designed and had cast. Where and to what detail level

this loco becomes remains to be seen but that is a part of the fun. That is

going to be the challenge is keep this somewhere closer to old school than a

huge involved project. Some of the original details are likely to be milled off

for brass parts added. If bad things happen in the milling process a

replacement boiler is available all over eBay for cheap. The biggest expense

was the 2 amp Tsunami decoder and Current Keeper I already bought.

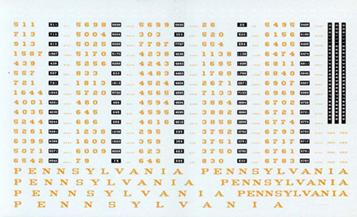

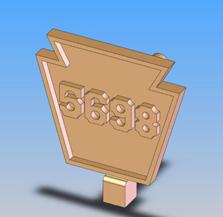

Prophetic Bill

Back

in January 2009 I was in a Solidworks train part designing frenzy making truly

anything I that could possibly want. It was 100s of parts including making my

many cast brass steam loco numberplates. I was

concentrating on making numberplates for the locos

that existed in S Scale and I owned at that time, but again for what I might

make in the future. A friend bought the remaining Onmicon

PRR parts that included brass partial drives and boilers. The idea of cobbling

a brass M1 boiler onto a K4 drive to make a K5 has been with me for many years

but I never spent any time or bought parts to make it. Still I did make and

cast a 5698 numberplate and added 5698 to the steam loco decal set that got

made. So that helped greatly that I thought ahead about the possibility of a K5

and already had those items as well. Getting a single new loco numberplate now

made in brass has been very difficult with the 3D printing suppliers.

Added 8-28-22

Can Motor #1

I

could not get the open frame motor to run on DCC so it had to go. Besides the

open frame motor was really huge. A smaller motor allows for more room in the

loco for a decoder and speaker. I have had this motor truly forever I bought at

a train show and decided it was finally time to use it. I do not know the

lineage of the motor but there is a chance it is U S Army surplus! It is just about the correct color.

I

recycled the original worm gear. I made the motor mount which is adjustable to

engage the worm gear. Much to my surprise this motor also had some DCC issues.

I cannot use the loco drive for electric pickup. There must be some connection

someplace to the motor that might not be as insulated as with most other can

motors. All power pickup is coming from the tender which I don’t like but the

trucks are pretty far apart if there is a brief power pickup issue. While I

don’t need the 2 amp decoder I bought for the open frame motor now Soundtraxx

has the massive Current Keeper which will also help with momentary power

issues.

American Flyer Tender Shell

I

decided to use a Gilbert American Flyer tender shell in keeping in line with

the old school build of the project. They are pretty cheap and plentiful if I mess

one up. The American Flyer tender shell is also really close to the correct

length where the Omnicon K4 tender is too short.

I

wanted to recess the floor sheet I made. Getting the shell lined up to be

perfectly horizontal in my milling machine vise was difficult. The shell is not

overly accurate. The corner posts did not get equally milled out. The screws

holding the original tender floor in place were 3-40. I did not want such large

screws. I drilled and tapped 3-40 screws with 0-80 threads and made the screws

into inserts. As I cut away the 3-40 screw heads I measured down to make a

common level for the floor sheet. This worked pretty well.

The

top of the truck bolsters which is really just flat bar is recessed from the

tops of the sideframes. I made .180 thick spacers from ¼” diameter brass round

stock and soldered them to the floor sheet. I somehow managed to get the back

tender beam in perfect height for mounting a Kadee Coupler.

The

wheels are NWSL. The trucks look quite far outward but that is how they really

were – see the above builder’s photos. I got a basic tender drawing to lay out

the truck placement.

Some

of this might be somewhat temporary. The back tender steps are missing. I have

thoughts of milling the back tender beam off and 3D designing a new beam with

steps and a draft gear. I will add very basic details like an air tank and

brake cylinder. Hopefully I can find an S scale water scoop.

Added 9-9-22

Can Motor #2

As

mentioned above the motor was not controllable while on the track and power on

to the decoder so it had to go. I decided to try a known factor of a Sagami

motor that I have used to replace open frame motors in the past. If a new motor

did not work it would likely have been the end of the project at least for now.

Completely isolating a motor from the frame with an all metal motor shell, worm

gear and drive shaft did not seem like much fun to me. I was not completely

convinced a new motor would fix the runaway control issue when I tested

conductivity of the green motor to other Sagami motors I had. They seemed to be

the same to me with the shell connected to the shaft etc. I used my favorite

22mm x 40mm motor which is great for S Scale diesels. It is also a similar size

to the green motor I was removing but I had to try something.

The

idea of rolling a ring to go around the motor to support came to me. I do not

use my MicroMark roller much at all but it is usually fun when I do. I recycled

the motor mount base and made a new bracket with the rolled ring. I was pretty

happy with myself!

I

made no modifications to the motor in case the swap did not work I can still use

in a diesel. Since I don’t use flywheels anymore I would usually cut the back

shaft off. But I seem to have some control over the motor now. There is a

random short someplace allowing it to only run for about an inch before

stopping again. Finding and fixing the short is next.

Added 9-11-22

After

some significant work it is finally running to some degree. A small part of me

wants to leave it as is as an American Flyer loco on scale wheels but that is

not going to happen. Now comes fixing some of the drive issues like the

eccentric rod not staying in place in reverse and adding whatever better

details I want. Some new 3D designs are in my head. What was a low budget build

is not so low now with the American Flyer parts I have bought.

This

project represents my biggest use of AC Gilbert American Flyer parts. Most of

the exterior is American Flyer. But this also shows how close to correct 1/64

scale American Flyer really were for being made as a “toy trains” especially

when compared to almost all extremely undersized Lionel products.

Added 10-1-22

Left turn at Bob Frascella

Most

long time S Scalers could go for many years and not see any American Flyer K5

converted to scale wheels. My freind Bob Frascella completely surprised me with his first S Scale project and let me buy it!

Bob’s explanation is below.

It has an interesting history and dates back to my earliest scale modeling efforts. In the early 70s, I saw a photo in the old S Gauge Herald of a K5 converted to scale by the late Sam Powell. The caption said that the conversion parts came from S Scale Loco &Supply. At the time I lived in the St. Louis area and so did Claude Wade and his SSL&S cottage industry. So I would visit Claude quite often and purchase enough parts to convert the K5. He walked me through the conversion but there was a lot of things that I had to figure out on my own with zero skills. It was my first S scale modeling venture. I sold the K5 to Larry Sokol in 1979. He used it for a few years and then wanted it repainted so he sent it to John Bortz who redid the fire box and upgraded the tender floor details. When Larry exited S scale he sold it back to for what he paid for it 25-years earlier.

While

I like the historic aspect of the Midgage

Models loco, for me it is about the detail and running well. Bob’s loco arrived

needing some work but was already much more detailed to a level likely well

above what I was probably going to achieve as the finished project with the Midgage loco. A drive based on Scale

Loco & Supply is more familiar to me. Also a huge improvement over the Midgage loco and all my other

SSL&S locos is this K5 somehow has code 110 drivers. It is my only

SSL&S loco with code 110 drivers. ALL the wheels will be code 110 when I am

done.

I

am not continuing work on the above Midgage

loco. Since the PRR only had 2 K5 I don’t need 2 myself especially with 3 brass K4. The Midgage

project will be sold – even though I almost never sell anything!

Bob Frascella’s loco as received on 8-26-22

A

rare photo of 2 American Flyer K5 converted to scale wheels. All construction

photos past this point will be of the K5 built by Bob Frascella.

Changing Motors

This

is the original open frame motor that has to be changed. Old open frame do not

easily work on DCC. They mostly are not insulated from the frame causing the

motor to run uncontrolled when on the track. The best and easiest thing to do

is just change them to a newer can motor.

New Canon Motor

I

had to make a reducing shaft extender for the worm gear. I used a ¼” bolt. I wanted

to use steel because I thought brass might flex. The extender shaft and worm

gear are all soldered together. Making new motor mounts has become rather easy

as well. The photo at lower right there is a slight amount of angle adjustment

to fine tune in the worm gear engagement. This motor runs REALLY well.

Added 2-25-23

Due

to the rarity of a S SCALE K5 I wanted to make a video

of both of them running together. But my usual modeling habits prevailed. I went

off into a Conrail and diesel modeling and buying binge in the fall of 2022. Someone

I know wanted the Midgauge K5. It went to a new home

on 2-25-23. I don’t need 2) K5. I liked the historic aspect of the Midgauge model but Bob’s build was much better and

detailed. This project has moved to be more of a restoration and upgrade then

the build of the first K5. It will likely be spring 2023 before I get back to

this.

Revised 2-25-23

All photos

and content © Lanes Trains 2005-2024