|

This

is Overland Models E7B 1799 made in 1984. At 1 time I had 14 brass E units so

I sold a A B A set of E7

in 2012. I currently have 3 Overland E7a, 3 Overland E7b, 1 Overland E8a, and

3 River Raisin E8a. The E8a is the only S Scale model to be made in brass

twice. The

original thought was to make a A B A set of E7 in

Brunswick Green 5 stripes, a E7 A B A set in Tuscan single a E8a E7b and E7a

set in Tuscan 5 stripe, and a E8a E7b E8a set in Tuscan single stripe. That

is a lot of E units and why I sold a set of E7. I am not sure how the mix

will come out now, maybe 1 in Brunswick green but the rest are going to be

Tuscan. I

get the windows do not match up perfectly to the PRR E7b. There is only so

much I can do. |

|

I

have been running a Overland E7a and E8a for a while. The

rest are unpainted for 20+ years. I am trying to get those long owned locos out

of the boxes. It was time to get at least 1 B unit running.

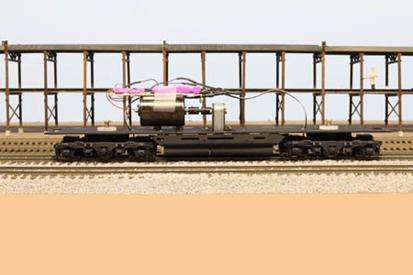

Drive

This

is their typical “tank drive” of that era. The first photo is stock right out

of the box. It is a small wonder that they ran at all with this drive. Only 3

wheels per rail pick up that would make it stall easily. The motor and tower

are not perfectly aligned with a piece of rubber tubing for a motor coupling.

That all had to go and get upgraded.

The

truck gearboxes had rubber tubing connecting them together. The shafts just

butted up to each other. There was not mechanical joint. I

HATE tubing on a model. It can slip on the shafts. On newer loco releases

the shafts were longer and cut in half so they keyed to each other in the 3MM

sleeve.

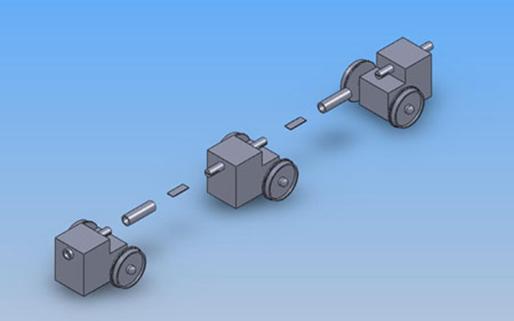

This

is what I did to get rid of the tubing on the trucks. I made 3MM sleeves x ˝”

long. A 3MM drill is PERFECT. I cut slots in the shaft ends with a Dremel cut

off wheel, and inserted brass flat bar. It all still floats and

adjusts with zero chance of slipping ever. I have done 2 units so far. It is

working well. The black truck is done with the upgrades.

I

have also backed off to making just 1 pick up per

truck for the insulated side. The decoder capacitors do a great job of keeping

the loco running.

I

was trying to get this loco running on the cheap. I usually would get the same

decoder for all 3 locos so I don’t have to get involved in speed matching. The E7a has a

original Tsunami I added a keep alive to. The E8a has a 2 amp Tsunmi2. They ran

perfectly together without any extra programming. I bought a 1 amp Tsunami2 for

the E7b. That turned out to be a ROCKET. I have never seen a brass loco run so

fast. I set CX 5 to 52 and CV6 to 32. All is better.

This

is the drive after my upgrades. Note the new NWSL dogbone

motor coupling. I usually have all the electronics up in the shell roof. There

are no headlights so I used a Miniatronics 2pin plug for the speaker. Note I do

not use the truck screws at all for pick up. There are 2 pin Miniatronics plugs

for each truck for direct power pick up.

This

is a mix of about 2/3 Scalecoat Tuscan and Scalecoat Oxide Red. I think the

Tuscan is too dark right out of the bottle.

Decals

Caught

in 1 of my obsessive “I have to have it” moods in 2008 I contracted with

Microscale to make single stripe E unit decals. Microscale had no interest in

stocking them so I had to buy the minimum run of 300 sheets – easily enough for

decaling 150 locos for $350.00 (I think). It has been 12 years now. I have not

used ONE decal set yet. That was another reason I wanted to get a E7b running.

Updated 7-31-20

All

photos and content © Lanes Trains 2005-2020