|

This

is a custom made S Scale Central Railroad of New Jersey Blue Comet train

built by the late Frank Titman I bought on 1-4-21. Frank was by far 1 of the

most prolific custom builders in S Scale. I am not quite calling this 1 of a

kind because Frank built another Blue Comet locomotive that I know exists,

and may become mine at some point. I am reasonably sure there are not any

more Frank built Blue Comet cars. Still it is a rare model I think is

important in S Scale history. This was Frank’s personal train he built for

himself. I consider the loco and 5 cars as one model. There will not likely

ever be more cars, certainly not built by Frank. Some of my build decisions

will be based on that fact. I

am not particularly a CNJ fan but I do like things built by Frank Titman. If

I was going to have something CNJ what is more iconic than owning the Blue

Comet? American

Flyer by Lionel made a VERY nice Blue Comet train but unfortunately none had

scale wheels. I was not overly interested in taking on more projects to get

scale wheels installed maybe on just some more cars. They would not match

anyway. So mine is the only known S Scale Blue Comet with scale wheels. |

|

The

loco was unfortunately stored in a bad environment causing significant damage

to the paint. The cars are in fair condition and need some work but the loco

needs total restoration. I am trying to keep this in as original condition as

possible. I hope to catch the sprit of Frank and return this train to its

former glory. Since I don’t know all what the loco was made from I have great

hesitation of how to strip the paint.

The

cars were TrainStuff kits that were made by Don

Thompson and his company before S Helper Service. The sides are polyester that

is likely very brittle by now. There is no replacing a shattered car side at

this point. I am probably replacing all the wheels with NWSL 36” code 110.

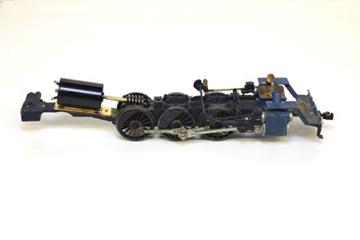

The

loco is built in typical Frank Titman style starting with a few American Flyer

parts and finishing with lots of S Scale Loco and Supply parts. It is mixed

materials but a large amount of it is brass. However this loco is significantly

heavier than my other Frank built locos. It is made to pull 5 light cars but

could probably pull a much longer train.

This

photos show all the work that has to be done. This will be by far the most

ornate steam loco I have ever painted. I nudged Tru Color into making a Blue

Comet blue paint. I hope it is close to what is here.

832

Photos

taken 1-13-21

I

took that complete train photo as inspiration of what it will be like when I am done and it is running.

Added

1-29-21

Working

on this started a bit sooner than I expected. I do have the Tru Color Blue

Comet paint but not the loco decals yet. I have learned about more about the

history of the real Blue Comet. I have also had some questions of my answered

about the loco since I took it apart. For the first time I have seen in Frank’s

builds the boiler is a rather heavy bronze casting with the American Flyer cab

and firebox attached. The casting walls

are about ¼” thick. Frank was a real man’s man for transforming this boat

anchor casting into pure S Scale art. Many of the parts attached have holes

drilled through the bronze casting at a significant effort possibly with a lot

of broken drill bits as well.

Updating The Drive

I

am building this to a slightly different standard. I view it as a unit train.

This loco will only pull these cars. It does not have to have killer slow

speed. Getting that with the can motor conversions gets down

to a difficult gear engagement when making the new motor mount. It can

be really time consuming. I tried to keep the giant Pittman open frame motor

but had DCC issues that I still don’t understand. The brushes were seemingly

isolated. The loco ran fine as an elevated bench test but ran uncontrolled when

put on the track with the tender. The tender is insulated from the loco with a

plastic drawbar. The PowerCab did not show there was

a short. I am missing something here but it does not matter because a can motor

conversion fixes the problem.

I

started off using the same can motor I have used in all other Frank built locos

can motor conversions I did in the past including the Reading G1sa I did just 2

weeks ago. http://www.lanestrains.com/S_Scale_Reading_G-1sb_201.htm

This should have been

identical conversion but it somehow was not. The larger diameter of the motor

the more I had to angle the motor to engage the axle gear. This was getting to

about 35 + degrees so I stopped. Again this only has to pull the 5 cars so I

went with a much smaller motor than I originally expected. It was almost a

straight shot to the axle gear. With the heavy cast boiler this motor struggles

a bit to slip but it does. I am not guaranteeing it won’t stall instead of slip

so I just have to watch for it. The steel driver tires are very grippy!

I

made an adaptor shaft from 1/8” brass round stock. The brass shaft is soldered

to the motor shaft. The worm gear is soldered to the brass shaft. The loco is

powered by pickups on the tender only. The loco has no power pick up wired to

the decoder. This is my typical pickup wipers I have made many times. I stopped

cutting grooves in the backs of the wheels because the pickups stay in place.

They do not short.

DCC

Since

the boiler is cast bronze for the first time working on a Frank built loco it

is heavy enough to not need to add a boiler weight. There is a significant

amount of clear space in the boiler. But the boiler front is permanently

attached making access more difficult. I decided to just make a slide in

decoder unit with a TCS WOW4 and RailMaster DLG8 speaker on a price of brass

flat stock. It is sort of free range in the boiler but it cannot slide into the

motor or gears. The sound is LOUD. I have the chuff volume set to 2%. Maybe

bouncing off the bronze boiler makes the sounds loud.

Loco Wheels

The

drivers had to be pulled about .015 total to the

current NASG standard. I replaced the code 125 tender wheels with code 110

Northwest Shortline nickel silver wheels. I replaced the lead truck wheels with

code 110 S Helper Service wheels. I sanded down the trailing truck wheel to

code 110. The drivers remain the only code 125 wheels left. I don’t know why

Frank made the center drivers blind on a pacific. But his layout had some very

sharp curves.

Cab Roof

Frank

chose to cut off the American Flyer roof and cab overhang. He laminated a cast

brass cab roof to the American Flyer cab with ACC or epoxy. The roof was popped

off when I got the loco. I probably could just have glued or used epoxy to put

it back on but that would be too easy. If it popped off once it could happen

again. I wanted a mechanical attachment. As usual I did not know how I was

going to solve my “problem” when I start but it just comes to me eventually.

Involving my lathe or milling machine to my projects just adds to my ongoing

challenge to myself. I soldered 0-80 flat head screws to the underside of the

cab roof as a stud. At first I was just going to use 0-80 nuts but getting a

nut started deep in the cab and using a nutdriver at

those odd angles might not have worked. I drilled and tapped 1/8 brass round

stock for 0-80 and cut a slot across the top to make a “tube nut”. I never saw

1 before but I made 2 of them. They pull the roof down tight. And I did not

have to MASK it to paint!

Added

1-31-21

I

took a new stack photo and shot a short video

. A working headlight makes all the difference for me almost more than a sound

unit. The loco is running pretty well now. I have to sand down all of the car

wheels to code 110 and regauge to NASG standards. The cars also did not roll

well at all. I will lube them all.

Added

2-3-21

Done For Now

I

am happy that this is out of the boxes and running in 1 month’s time, much sooner

than I originally expected. The loco is running really well now. I let it run

for about ½ hour that really helped smooth out the jerkiness the loco once had.

The loco still needs to be repainted. I

am trying to get new decals made. The cars are pretty much done with almost no

touch up paint needed.

I

Diner Repair

The sides on the diner were detached about ¾ of the length of the

car on both sides. Fixing that was 1 of the most difficult stressful repairs I

have ever done. The floor was warped upwards and the sides warped outwards.

Luckily the roof was removable or I could have never fixed this car. A

significant amount of ACC (Zap A Gap Green) was used but it did not stick to

the sides or wood quickly. I had to use Irwin Quick Grip clamps

to hold the sides in place – 1 at a time, with the roof back on to set levels.

How I got this all done without shattering the polyester car side or have any

visible glue marks on the car sides is a miracle.

Car Wheels

The biggest job on the cars was replacing wheels. I wanted to get

Northwest Shortline wheels. 3 weeks after first contacting them about stock I

have not received a reply if they could supply the wheels. So I tried to

recycle the original wheels that I have thrown out wheels just like this in the

past. That meant sanding down the tread by removing .015, then regauging to current and wider NASG standards and

repainting them. I spent HOURS working on the wheels only to find they still

shorted out because the center hub of the wheel was now wider than the tread

and contacted the sideframes. How annoying. What a waste of time. I replaced

all of the car wheels with Downs code 110 36” wheels I

luckily had. Code 110 36” wheels are tough to find right now. The drivers and

trailing truck wheel are original but were worked on. All the rest of the

wheels on the entire train where changed. The couplers were truck mounted on

long shanks. I don’t allow truck mounted couplers so I body mounted the

couplers on the cars.

There is a new YouTube clip of it running here.

I will make a new clip whenever the loco is repainted and done.

Added

7-22-24

Another

Blue Comet Loco

833

This is the second of 2 Frank Titman built Blue Comet loco that I

referenced above. It was originally owned by Don Thompson. Frank built it for

him. I remember seeing it many times at Don’s house in New Brunswick NJ but I

never saw it run. Don’s comments are

below. I got the loco from Jay Soberman on 7-19-24. It was a gift from Jay to

me as well.

I asked Frank to build this loco for me more than 40 years ago!

It was while Robin and I owned Train Stuff! Frank crafted the tender truck

patterns based on a CNJ drawing in one of the Locomotive Builders books! I used

a RTV mold and spun cast in pewter. The lettering was from the late Tony Perless and then he made the dry transfers. The dent in the

cab roof is from falling out of the display case. The tender is Marx’s, the cab

from a AF Atlantic, boiler and brass lost investment

detail parts from SSL&S. In 2013 Mike and I sold S Helper Service and I was

told Robin and I were selling our house of 37 years and moving to a 37’

sailboat. As much as I loved this gem, it would not fit. I gifted it to long

time buddy and S Scale dentist Dr. Jay Soberman.

This loco is significantly different than all other Frank built

locos I have. Maybe because the differences are something Don asked for. All

wheels except for the trailing truck are code 110. This loco has much better

detailing than the loco Frank built for himself. I do not think they were built

together but I have no proof of that.

These

are photos taken as received from Jay

7-21-24

It’s

Alive

Added

7-28-24

Since I had 1 I used a TCS KAM4 decoder just to run the 3MM LED

backup light. I put a resistor across orange and gray to simulate motor load. I

thought it was rather ironic that both cab roofs had to be repainted. They are

not matching at this point. I switched to NWSL nickel silver 36” wheels for the

tender. Just like above the electrical pickup is from the tender only.

The drive rolls very freely but there is still some binding when

the motor is attached. The slow speed running is not as good as 832. This

already had a can motor installed when I got it. I used a 2 amp Tsunami2

because I had 1 I was not using. I would like to install a 22mm x 40 mm Sagami

motor and TCS decoder like 832 has but surprisingly they somehow both come

together and run pretty well at about speed step 5 on the NCE handles even with

a different motor and decoder. The paint is much better on 833 but is still a

bit rough. I am not sure when or IF I will repaint either of them. Just like

832 I am not completely happy with this loco but I am done for now…..

I doubt the Blue Comet would have had 2 locos for 5 cars but they

do look good together.

Frank

Titman Tribute

At the 2024 NASG Convention in Harrisburg PA Hugh Sinn and I put

on a display of Frank Titman made trains we own. There are LOTS more “out there”

owned by others now shown here. Jamie Bothwell and Jim Whipple bought a few

other pieces. That is where I saw 833 for the first time.

Updated

7-28-24

All photos and content © Lanes Trains 2005-2026