|

This is Overland OMI1712 USRA 0-8-0 switcher imported in 1986.

This is from what I always called the “Golden Age” of Overland with really

nice models for their time. There was also a NYC Hudson, USRA Pacific and

USRA Mikado made. They have cast frames that are blackened and are just

really full of details. This loco has particularly large drive components for

an S Scale loco. I think they were made for O Scale. The driver axles are almost

6MM in diameter. The axle bushings are the biggest I have seen on a S loco. The 0-8-0 was always a favorite but the PRR only had a few

that ran in Ohio. A 0-8-0 craftsman kit was made by S Scale Loco &

Supply, but I knew I would never build one. Most of the real USRA 0-8-0 were

New York Central which I have never followed. I had an American Flyer 0-8-0

as a part of my original trains. Very few American Flyer steam locos had an

operating coupler on the pilot making the 0-8-0 special. |

|

I have wanted an Overland 0-8-0 for a very long time, just

replacing the American Flyer loco with a scale version. The clear vision tender

version seemed difficult to find. In June 2022 one came up for sale on eBay so

I bought it.

B&O

0-8-0

The B&O did NOT have any USRA 0-8-0. Their 0-8-0 was made by

modifying other existing locos. Besides the wheel arrangement and using a clear

view tender that is about where the USRA loco ends similarities with what the

B&O really had. There was no way I was going to try and make a PRR C1.

According to Wiki for

the list of real USRA 0-8-0 owners Southern was the only one with ANY interest

to me but I was not going to put that much money in a minor interest railroad.

I like the Southern high hood diesels but I am not

diverting into Southern steam. Ironically the decision to buy the loco hinged

on if I could find a River Raisin Models B&O emblem for the boiler front. I

found it quickly in the tonnage of my spare parts so I guess buying the 0-8-0

was meant to be. I chose 848 as the loco number because it is the first 3

numbers of my phone number truly for my entire life. This is by far my most

expensive foobie project.

This is the model straight out of the box without any work

started. In the past I have frequently taken the first project photos at some

early point after some work was started. Completing any brass steam loco is a

lot of work but since I m not chasing any prototype

this project is all but going to be a paint job. I am changing the headlights.

New

Motor

The first thing I noticed was the usual large Overland Sagami

motor stuffed into the boiler. There was less than ¼” between the motor and

tower leaving no space for any real U joint coupling. It was cogging because

the motor and tower shafts were not aligned well.

The

motor that was seemingly in everything Overland S made from that time truly

JUST fit. If it was another 1/16 larger in diameter there is no way it would go

into the boiler. I did not like the short and jammed in motor coupling that was

obviously cogging and difficult to align. There was no room for a U joint as

is.

I

have maybe 50 motors in my driveline parts box. I have changed lots of motors

especially for American Models GP. This is likely the first time I have ever changed a motor mostly

because I wanted one that was smaller. Once you have driver slip it really does not matter what size

the motor is. A smaller motor also allows for more space for a decoder which

turned out to be very needed.

I hated

to neuter my favorite dual shaft motor 22mm x ___ (various lengths) but this is

a Sagami 22 x 36 that is awesome in S diesels. I found a Sagami motor that did

not cog (22361-9) and knew that was the one. The goal is to get your U

joint/motor coupling to do as little as possible because the motor and tower

shafts are really already in alignment.

Photo

below is the drive as built by Overland with the original motor coupling. Sorry

the loco is off the track!

These

photos are after the new motor is installed. It is an Overland U joint as well.

New

Gear

I went

from receiving my new to me Overland 0-8-0 on a Friday to breaking the lower

gear on that Sunday afternoon. I test ran it for less than 5 minutes.

Apparently it was a common problem because it is an old nylon gear. All I could

think of is I now own an expensive boat anchor if I cannot get a new lower gear

for a 35 year old loco. It is NWSL Part 2285-6 and they had it in stock. I was

running again in a week. Thank GOD for Northwest Shortline!

I was really sweating it for a few days.

Sound

Cam Wiper

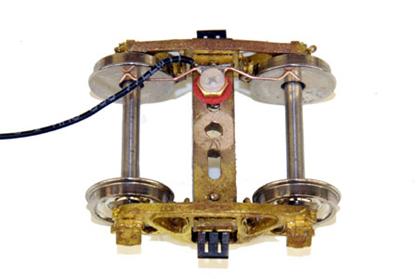

This

is the sound cam wiper on the 0-8-0 of my own design. They all vary slightly

depending on the loco, but I have many 100s of hours running with my cam wiper

design. It is easily on 12 of my brass steam locos. The 2

screws at left hold the wiper in place. The screw closest to the cam is

a fine adjustment that is actually applying pressure in the opposite direction

of the other screws. The sound cam on the lead axle is usually a problem

especially with soft axle springs. I have changed the springs in the past to

lock the axle in place and not spring. Otherwise with the axle floating a bit

it can make the wiper occasionally skip contact and chuff beats. It is a bit

annoying. Others say this can all be programmed without a cam. For now I will

stay with my mechanical cam wiper.

Running

on 7-4-22

I

changed the front headlight to a Pyle from River Raisin. The tender back up

light may get changed to the same headlight casting. I have to add pick up

wipers to the tender trucks for the decoder just to run the backup light. I

hate having wires go between the loco and tender. It has a TCS WOW4 decoder

with Keep Alive. The motor change made this loco run amazingly well now.

Tender

Added 7-10-22

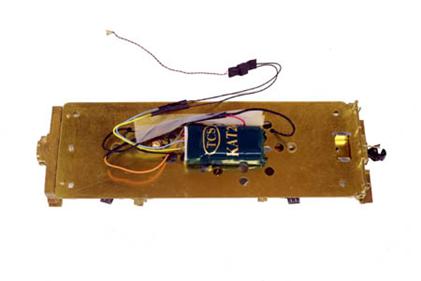

There

was not much planned for finishing the tender, mostly just get the backup light

running. I added pickups to the insulated side of the trucks to make it self sustaining. I got a TCS KAT24 decoder just to run

the backup light that has a built in Keep Alive to stop any light flicker. Yes

this is about $50.00 so I don't have wires running from the decoder in the

boiler to the tender for the backup light. I HATE that. There is a resistor

across gray and orange wires to simulate motor load. Programming will not work

without that. I tried a function only decoder years ago and could not get it to

work. It probably did not have a Keep Alive as well. I stick with what I know

and what works.

There

was an odd conduit starting at the front of the tender and running down the

side to the back as a power feed for the rear headlight. You can see it in some

of the above earlier photos. It is correct for the USRA locos, but I removed

it. It was annoying to me just ending in mid air as a wire that could cause a

short between the loco and tender. I also made a new longer tender pin from

nickel silver round stock.

I changed

the rear headlight to the same Pyle casting I used for the front headlight from

River Raisin Models.

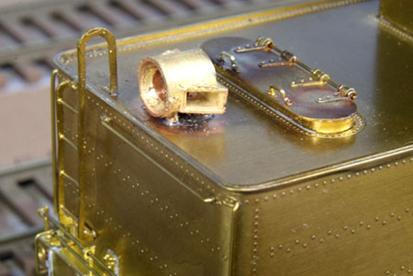

This

loco was missing the ashpan castings when I got it. Thanks to Vince Brunette I

was able to borrow a set and design them in Solidworks. There were some rivets

on the original castings starting on the bottom and wrapping around the side

that I did not make. I don't know how to make rivets on a round surface. The 2

bars in between the castings are scrap. That is so Shapeways does not count

them as 2 parts and really jack the price. I got 1 in brass and 1 in fine

detail plastic that was $90.00 alone.

I

am almost ready for paint now!

Revised 7-10-22

All

photos and content © Lanes Trains 2005-2022