|

|

|

Continuing

in my GP diesel run over the past year plus, I have wanted a PRR GP9b for a

long time. I had seen 1 made in S Scale many years ago that I tried to get from

the builder, but it was ironically destroyed in the 1994 Northridge Ca

earthquake and thrown out! It is a bit new for my modeling era. The first group

of 30 was delivered in 1957. That was the excuse to NOT build one for many

years.

But…. I have just come to accept the fact that

I like to build stuff!! Since completing

my GP9 7006 and GP30

2224 a GP9b would fit in well. It can run with both of them.

A False Start

In June

2017 this sort of GP9b project was offered to me by a friend that he bought on

eBay. It had a number of brass parts attached, and brass pilots. In March 2018

on closer inspection the lack of any steps was mostly a deal breaker for me. It

was TOO much work to make all new steps. A brand new shell was ordered from

American Models. I later saw more errors. There are NO numberboards in GP9b.

This shell had them cut open. All GP9b had 3 fans, not 5. There is a small

single chime horn in the center of the cab roof. I will reuse the 3 chime

forward horn elsewhere. So the decision to start all anew was good. Note the

odd screw on brass pilots. I would have liked to have seen what the builder had

in mind for the steps. If the steps were completed I may have used this shell.

There may be some parts I can recycle for the new loco but it will mostly be

all new.

A New Beginning

This

is the new shell. I was happily surprised that the numberboards were not open making

the GP9b conversion much easier than the bodywork of filling in the holes. I

just have to sand off numberboard outline. This is going to be a medium build,

not too crazy. I am not replacing the steps like I did on my GP9 7006. No

antennas or cab crew are needed. The handrails are going to be the most

involved part to make. This is my first new build like this in 29 years! It

should be fun. Luckily, Bills Train Shop ( BTS ) has kept the brass

detail parts needed IN STOCK for OVER 30 years.

I

decided the first thing was getting the new cab and 3 brass roof fans

installed. Some significant work was done to get the cab in place. After

looking at photos it is flush to the carbody. I had to remove about .020 from

the cab walls to get them to fit flush. Some sanding of the cab roof was needed

as well. I recycled the center fan panel from the first shell. I made fan holes

so the sound could vent. I discovered the brass fans have a legacy as Kemtron

36” O Scale which is currently sold as P&D Hobbies item #1075. With the new

fans on I could install the sound unit (TCS WOW4) and headlights.

Photos taken 4-8-18

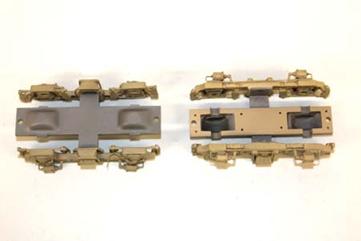

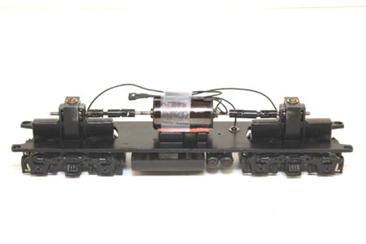

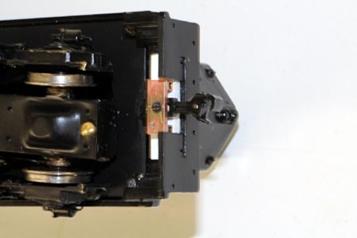

The

original builder was an expert machinist. I just wished I knew why some things were

done. There was .040 brass spacers added to the inside of gearbox cover, maybe

to get the journal boxes in a better alignment for the axle centers. This

caused the axle gears to not mesh well. I had to make axle bearing shims to

engage the gears. Since I decided to mount the draft gear on the shell the

coupler pad on the fame was cut off. The original motor touched the shell so it

had to go. I installed a Sagami motor. I try to get the motor shaft and tower

shaft as straight as possible so there is not much deflection for the

driveshafts. There is a piece of 1/16” thick rubber under the motor as a

spacer. The driveshafts were made by Overland.

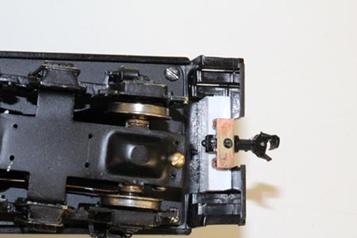

Draft Gear & Couplers

Since

I am not doing any 3D printing right now I knew that the draft gear was going

to be difficult. After looking at my various brass

draft gear I decided none would work. It was going to be old school make them 1

at a time. I laminated .080 x.25 wide Evergreen strip

to be .32 thick which is the distance for the top of the coupler to ride on.

The couplers are on and functional but are just not pretty yet. I still have to

make the draft gear. It was a pretty simple fix. I spent 10x more thinking

about how to do it than it took to get it done. I made a small bracket to hold

the coupler in place and center up on. They have to stick out much more than I

originally thought to clear the draft gear and provide space between the locos.

I

was having an issue getting the coupler heights correct as 1 end was higher

than the other which did not make sense. It turned out to be a washer in the

wrong place but was discovered after I tried some more milling. The Big Green

Machine ate the frame and turned it into trash in ½ second flat. Luckily I had

another complete GP9 drive. New frame was in place and running in 1 hour.

Updated

4-18-18

All photos and content © Lanes Trains 2005-2018